KnowHow that helps

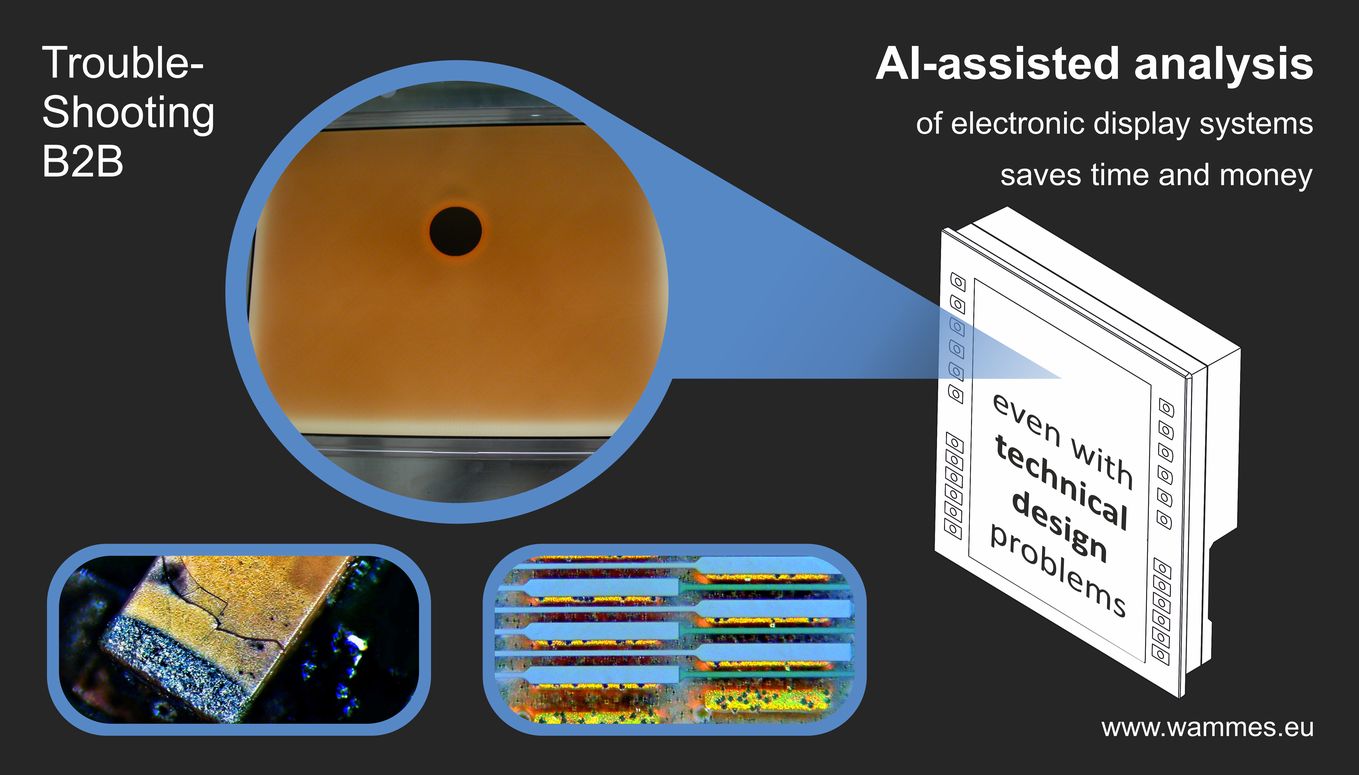

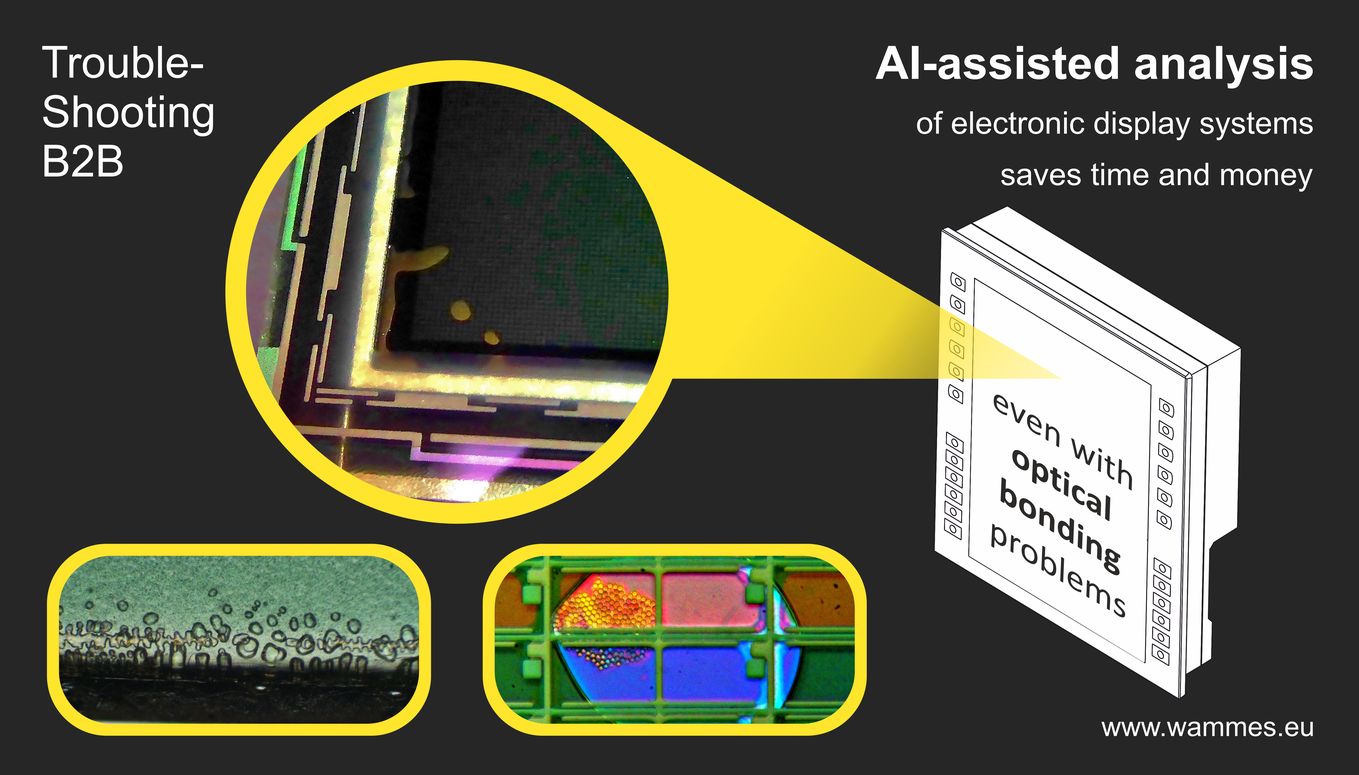

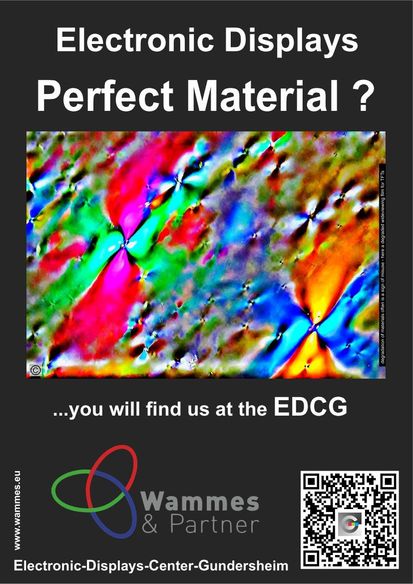

Beginning delamination of the bonded layers

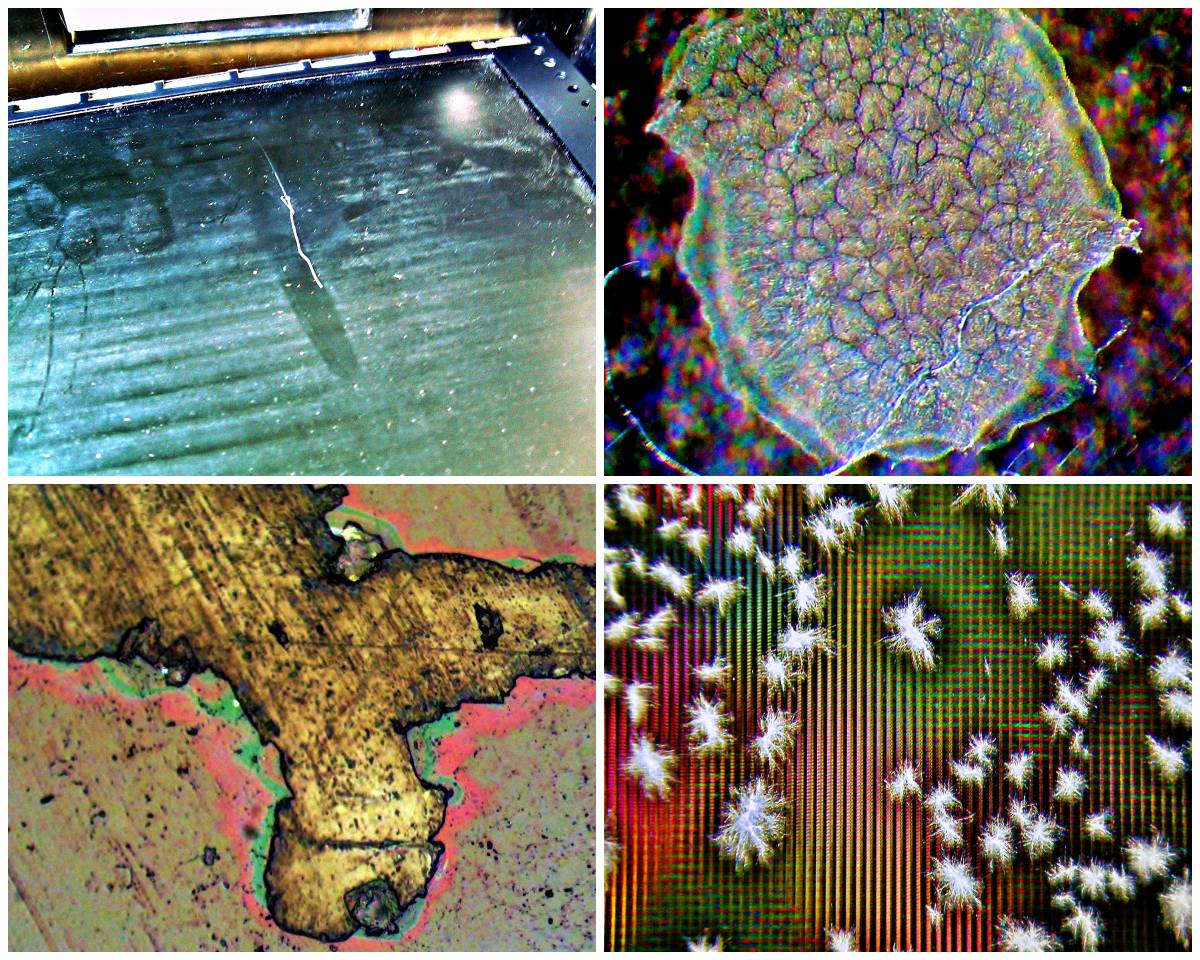

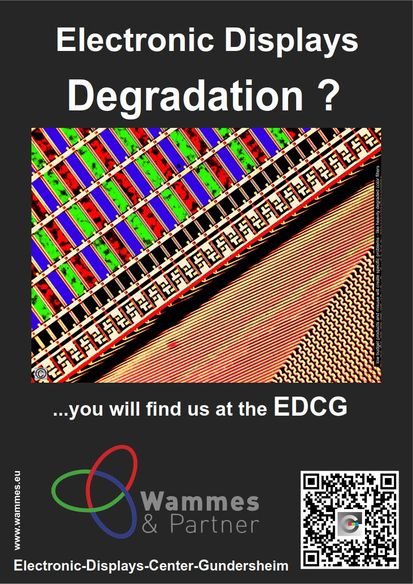

degraded - overloaded - hard-coated display or touch surface

an "anti scratch" touch surface after improper cleaning

massive mold infestation on the display front polarizer of a wrong systemic solution

the ITO-layer of a glass touch sensor degraded into very small fragments

degraded "ITO on PET"-layer of a touch sensor

Mold in the optical bond

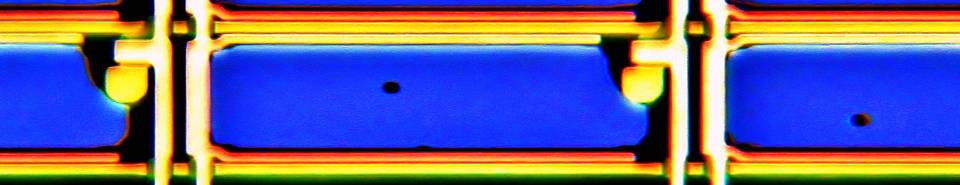

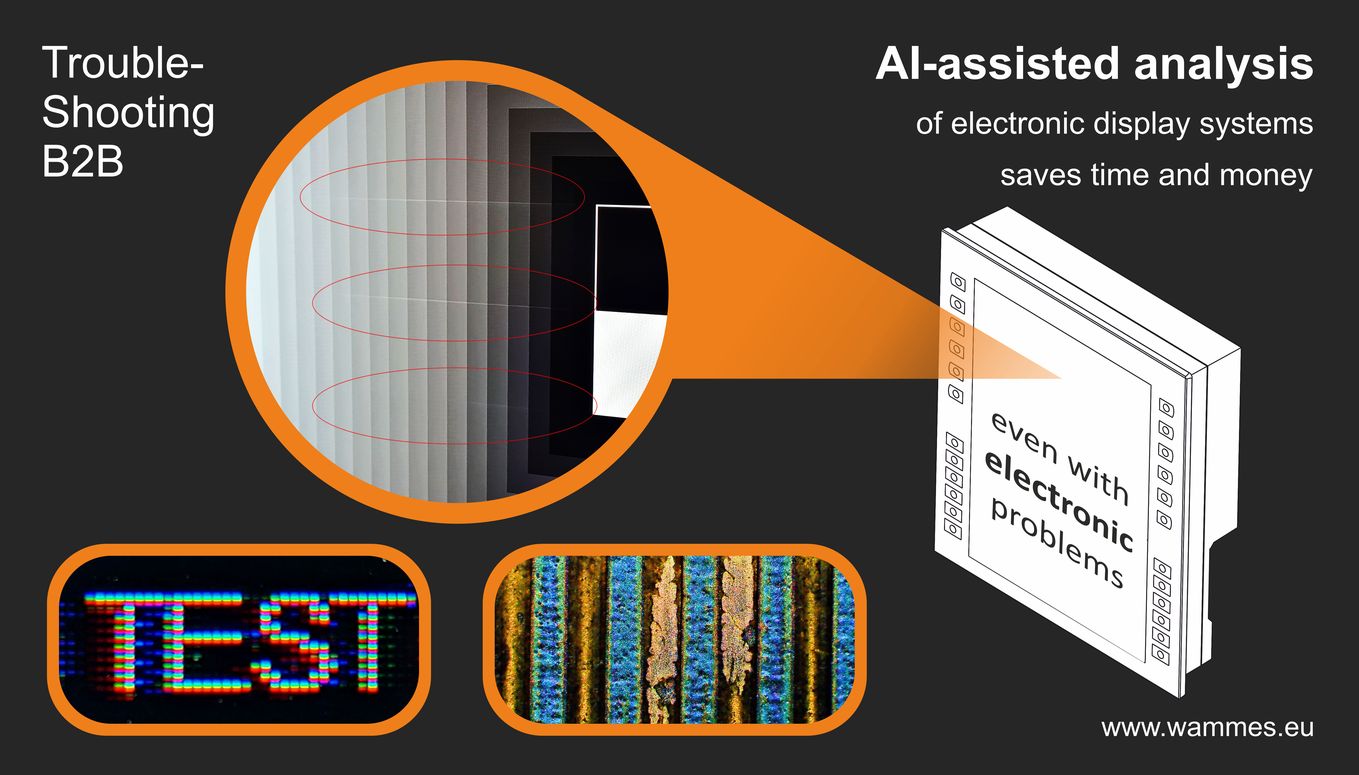

Humidity due to capillary action in the BEF-film of backlights

Cleaning artifacts and bubble formation during optical bonding

non-compensated thermal expansions of different materials lead to failure

unstable and unsteady signals in the control lead to flicker and other disturbances

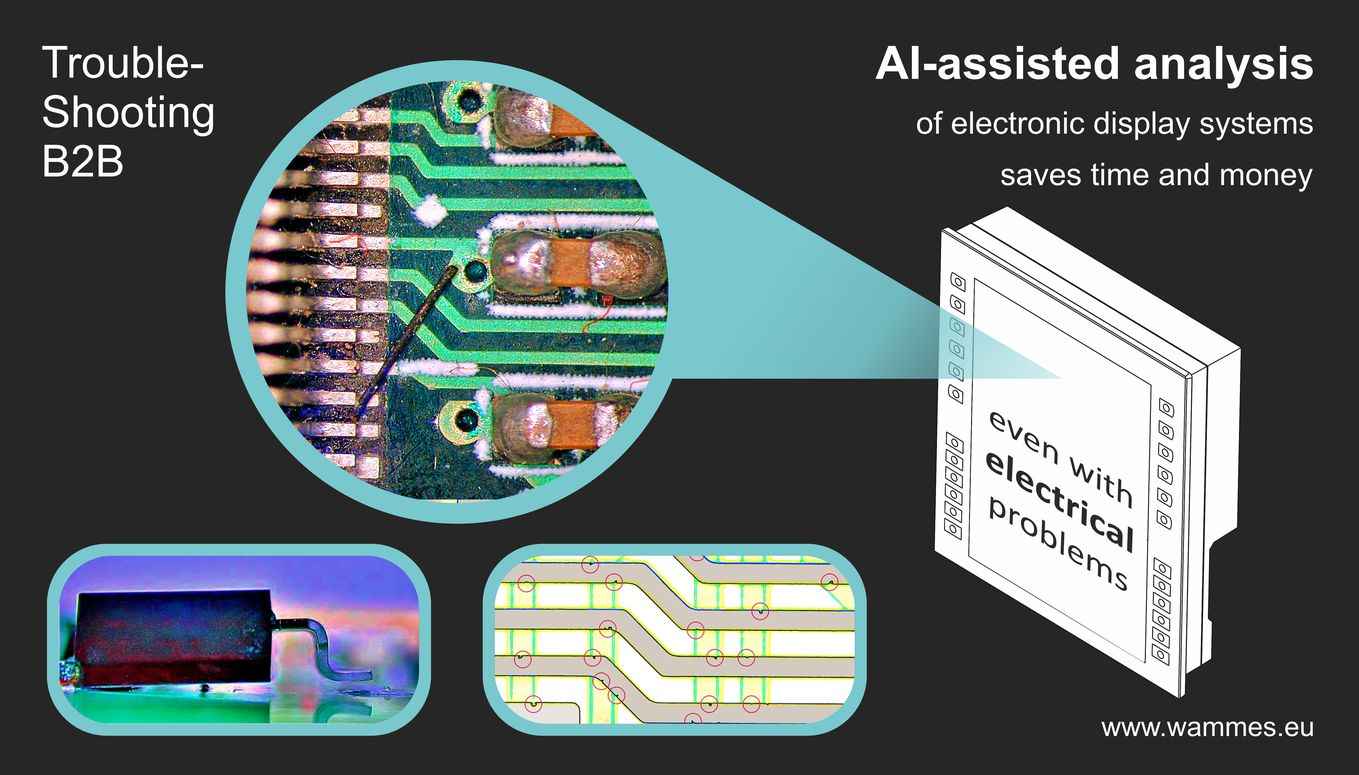

metallic and organic fibers from system integration for display problems

bad cables or bad line routing cause jitter and reflections in the data lines

incorrect timing for the display drive creates visible artifacts

leaking housings bring protective particles right into the display

unsuitable materials evaporate and condense with massive temperature changes

local change of retardation by material degradation create ghost pixels

Liquid crystals can also degrade - depending on quality

Display matrices are made of very thin glass - and break when integrated incorrectly

subsequently cut displays often have sealing problems - and corrode inside

thermally overloaded driver IC`s create faulty displays

chemical-physical degradation makes touch sensors unusable

Wetting-Effect optical films of unsuitable surface properties "stick" together

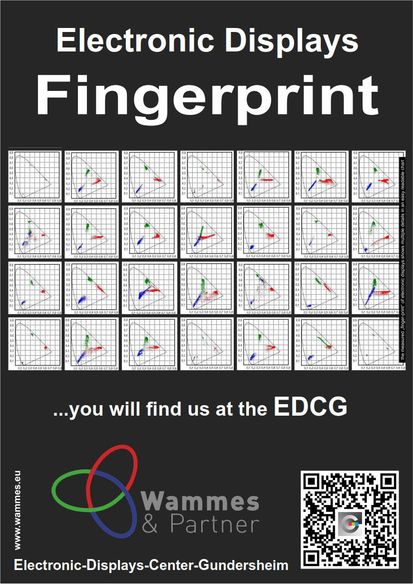

the display via the viewing angles depends on the optical design/properties

re-sized Displays often have unstable seals and are therefore less resilient

uncompensated shock and vibration generate local stress generates broken contacts

local change of retardation by material degradation create ghost pixels

"refurbished displays" only bring cost savings at first glance

Moisture in display systems leads to irreparable damage

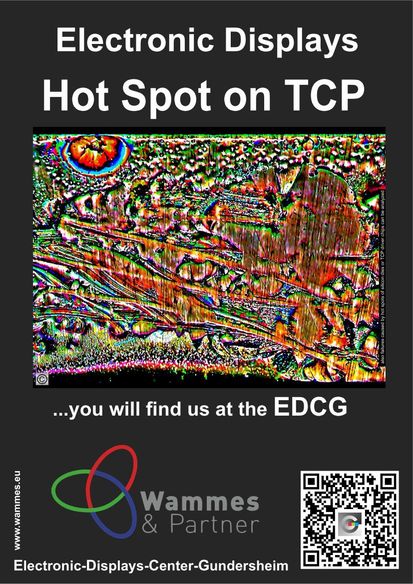

Local thermal hotspots lead to overheating of driver ICs

cut displays often have problems at the "interfaces

clumsy construction and unsuitable cleaners destroy seals

Displays for humid environments require special constructions

Wrong GND concept and flashed wiring lead to massive EMC problems

Clumsy device design allows accumulation of contamination in critical areas

ACF areas (anisotropically conductive adhesives) are mechanically very sensitive

this is what the microscopic analysis of a good quality BEF-film looks like

No trick! The chair has no hole and yet everything underneath is illuminated!

this is what a microscope image of a poor quality BEF film looks like

2K or 3K optical bonding adhesives must be mixed well otherwise there are optical problems

electronic components usually don't like heat - this also applies to the TCPs of the display drivers

After Imaging/Ghost Images usually occur when combining several problems

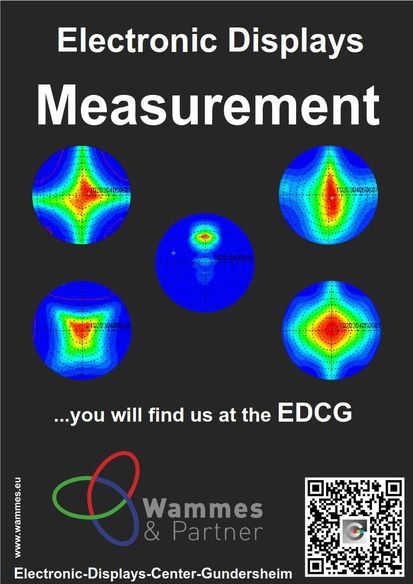

Uneven illumination and similar problems often depend on the technical design

partial rows and column errors usually hang

Yellowing of the display area is mostly due to unsuitable material for the given application

LCD-Displays lose their display in the places that get too hot

KnowHow that helps

KnowHow that helps

KnowHow that helps

KnowHow that helps

KnowHow that helps

KnowHow that helps

KnowHow that helps

KnowHow that helps

KnowHow that helps

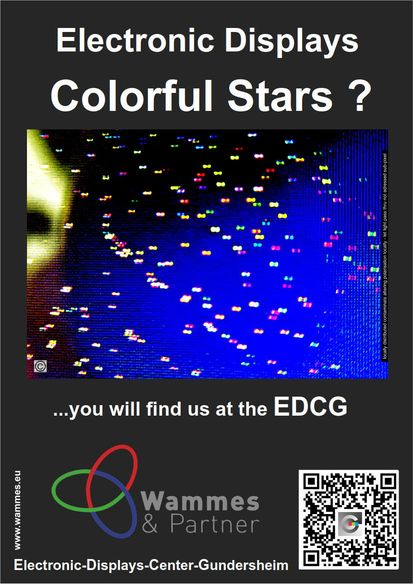

This MURA starry sky is evidence of an unsuitable material combination for this application

these MURA clouds indicate mechanical problems in the installation

the input ranges of the light sources are not compensated