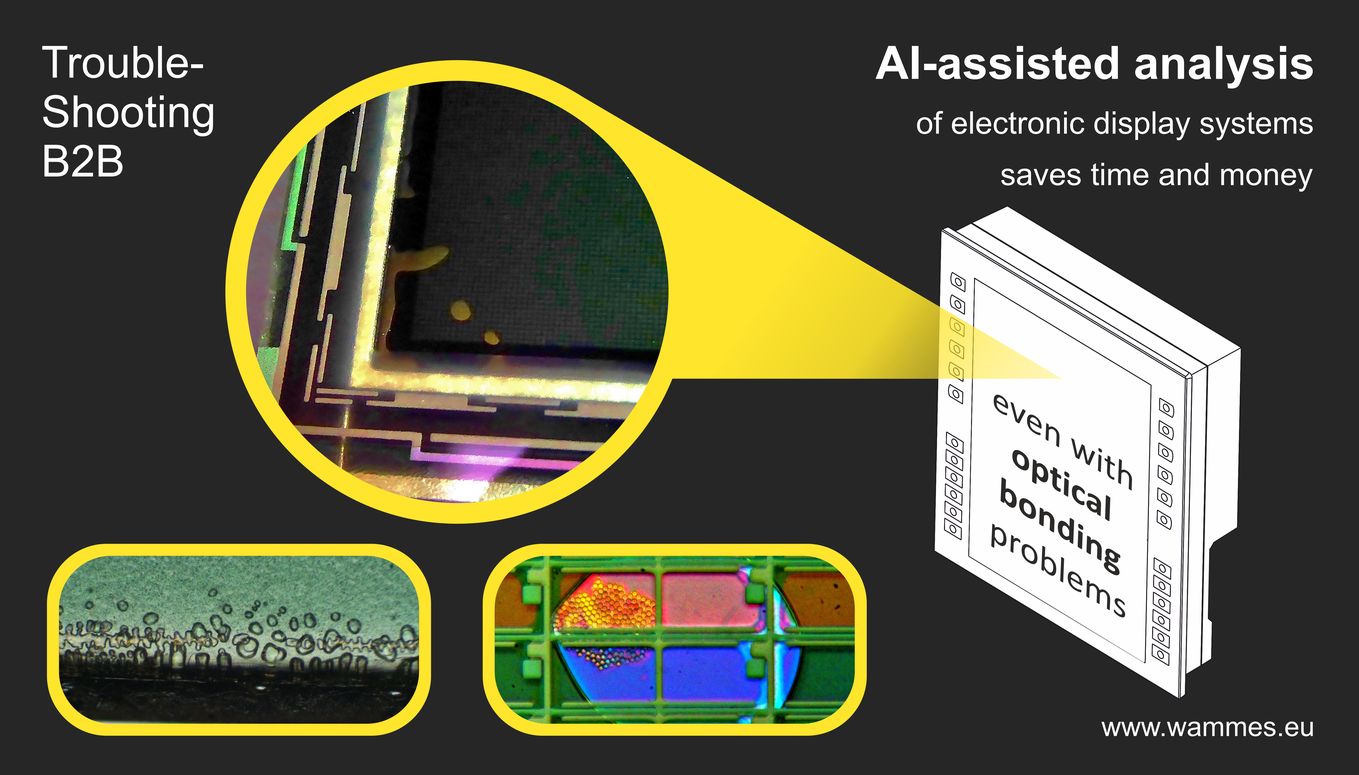

25 years of B2B Display TroubleShooting

What has changed - and how to benefit from our findings?

We are busy with electronic displays for more than 30 years now - and have data for display Troubleshooting for more than 25 years.

Our data and experiences are B2B only - no B2C like malfunctioning TVs or mobile phones based on user problems.

Our data and experience covers display system integration with problems of CTE, EMI, mechanical, electrical, thermal, bonding, signalling, design-in and many other - and also display/modules themselves like problems of design, processing, material, quality, aging, understanding of specifications and related.

Within the last 25 years we have seen a lot - and not necessarily changes for the better.

We now share our data and experiences with our customers offering consulting, training, workshops and education.

Which problems are most common?

Our customers hit list from the last 25 years – by number of cases

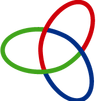

- electrical problems (equipotential / potential equalization, GND-concept, cables, connectors, oscillation tendencies, EMI etc.)

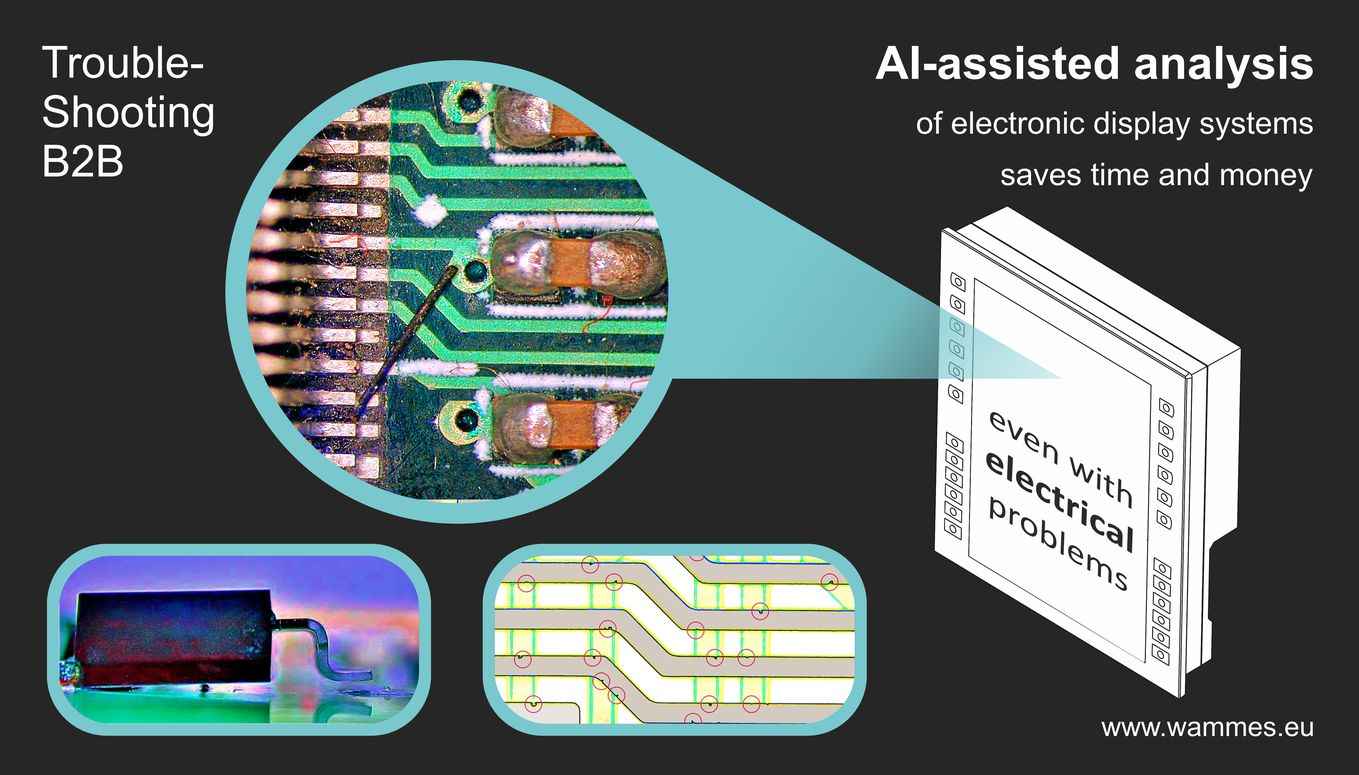

- tech. design-problems (wrong parts, combination of inappropriate components, wrong processes and parameters etc.)

- mechanical problems (expansion coefficients, tightness, shock, vibration, tension etc.)

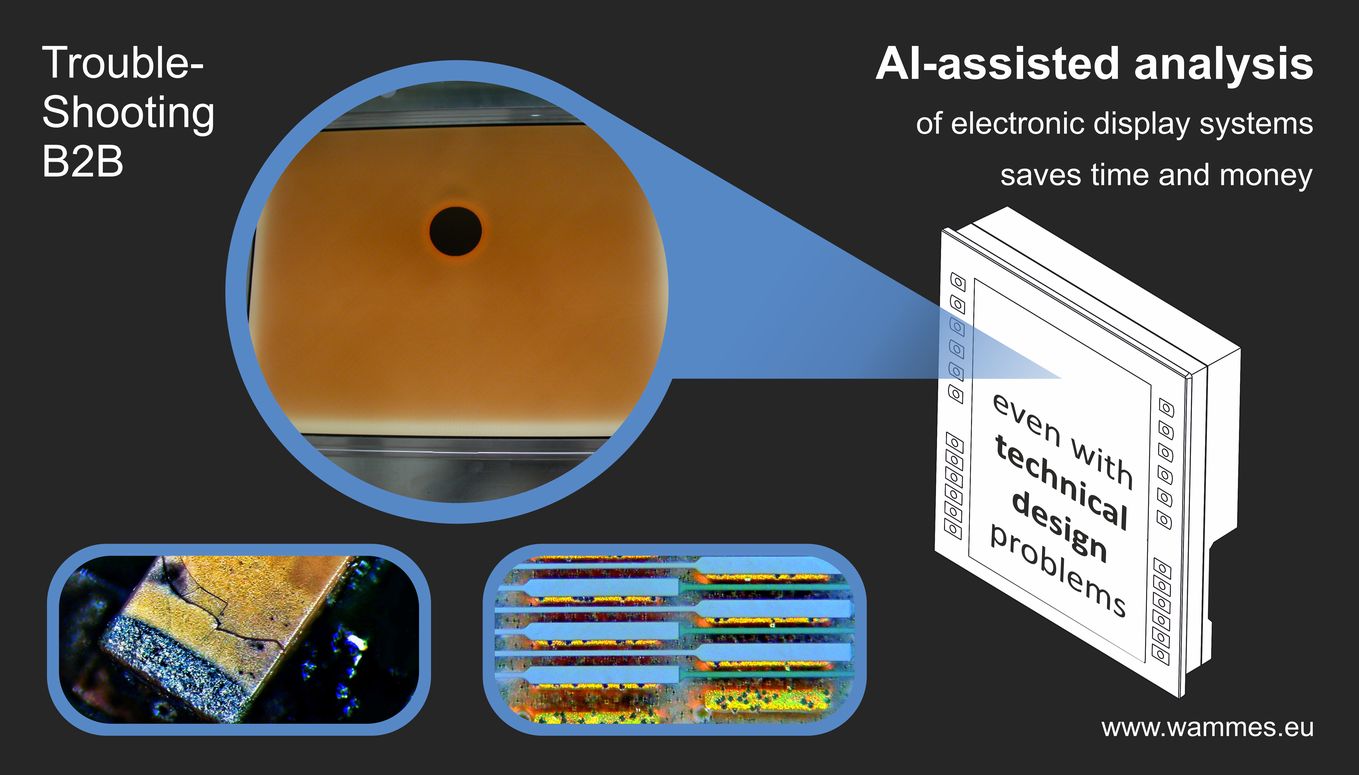

- electronic problems (control, timing, levels, interference, layout, processes etc.)

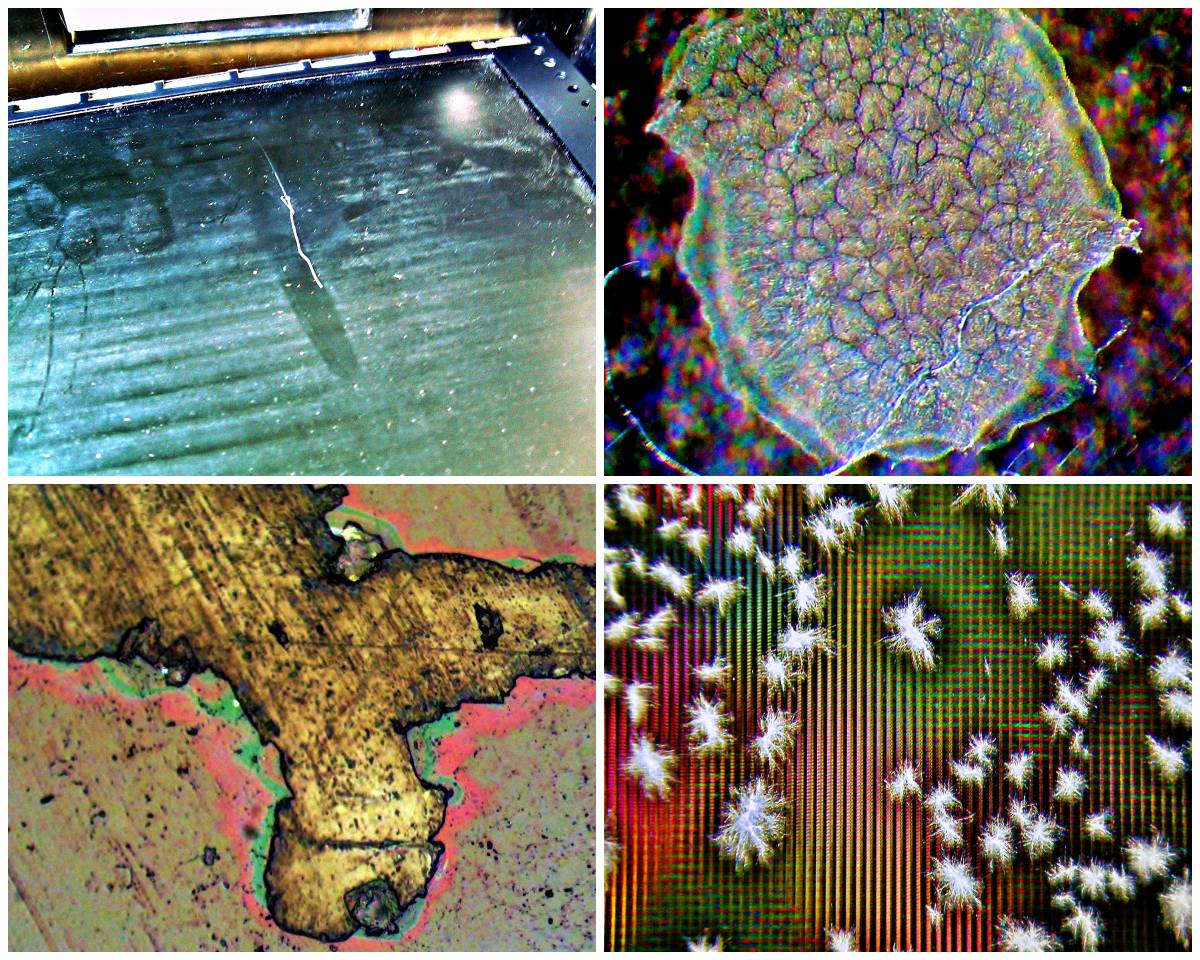

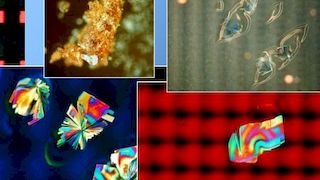

- optical bonding-problems (bubbles, blisters, delamination, contamination, streaks, inclusions, yellowing, materials, processes etc.)

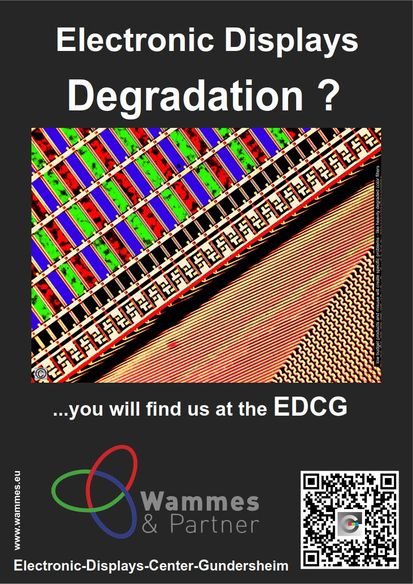

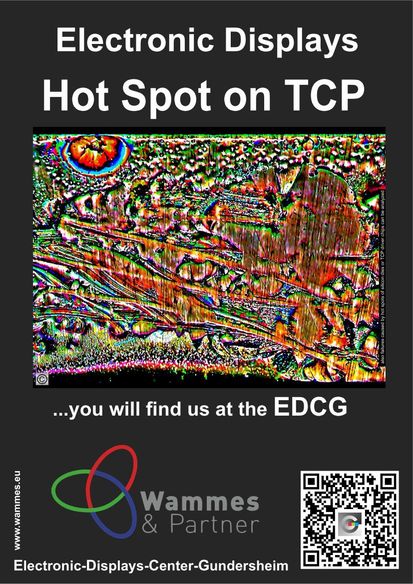

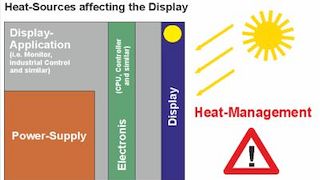

- thermal problems (hot-spots, cold-spots, packing-density, heat dissipation, degradation etc.)

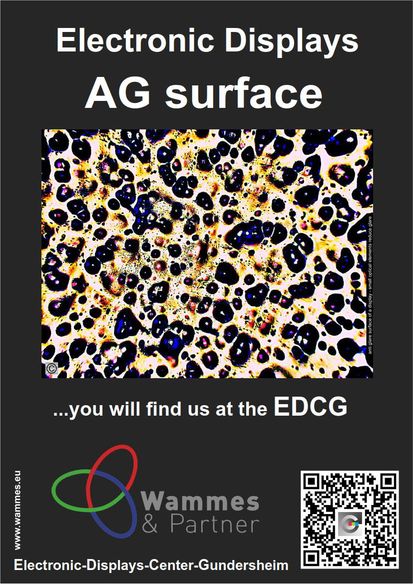

- Touch-problems (degraded seals, hermetically sealed seals, ITO- degradation, disintegration of coatings, ghost-touching, driver, maltreated surfaces etc.)

- chemical problems (moisture, corrosion, yellowing, solvents, cleaners etc.)

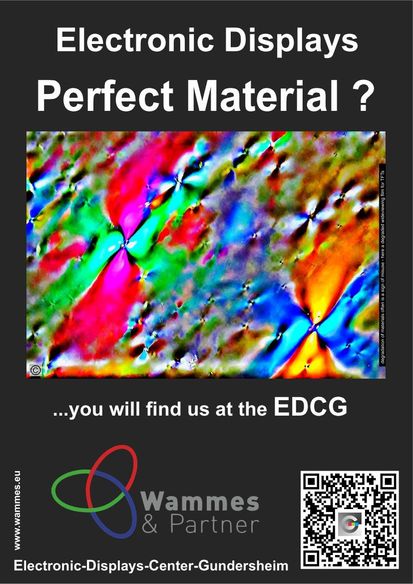

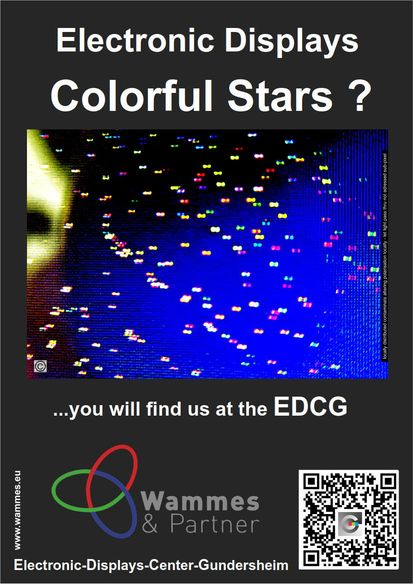

- optical problems (polarizer & retarder-orientation, light- sources, light guides, reflectors, optical films etc.)

- Bio-contamination (mold, fungus, vermin, germs etc.)

What in detail are we doing?

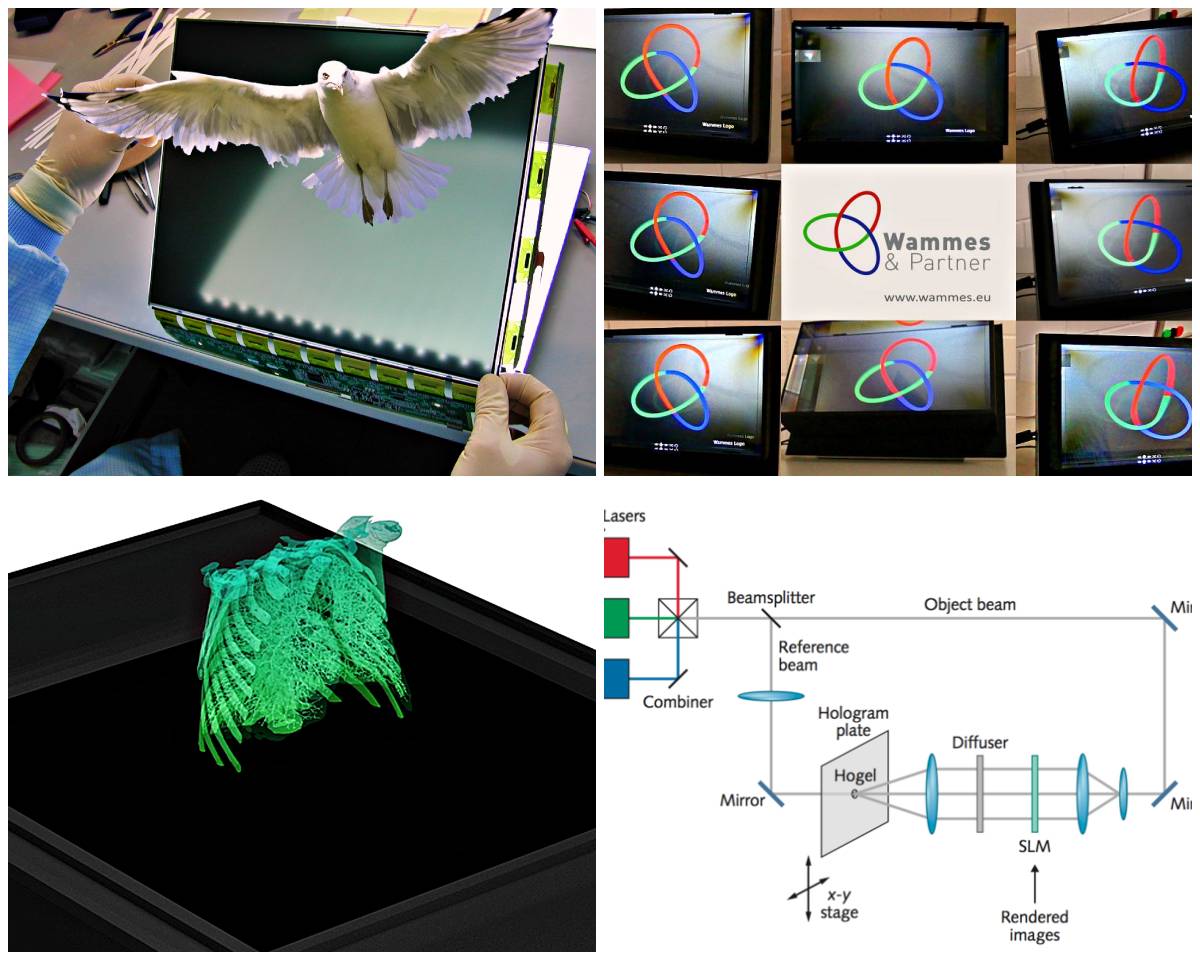

R&D for optical bonding of various shapes, mat- erials, processes and analyzing their quality

Failure analysis, bug fixing and trouble shooting

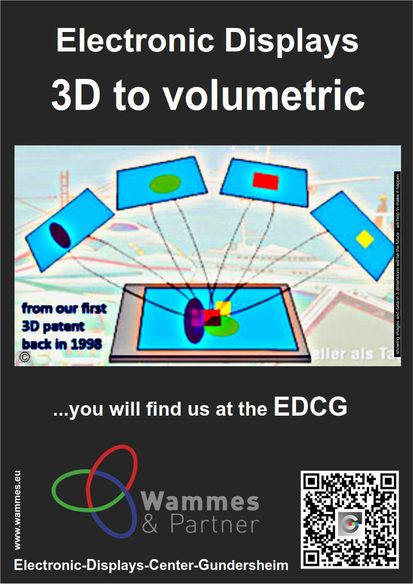

R&D for new hybrid, 3D and holo-displays

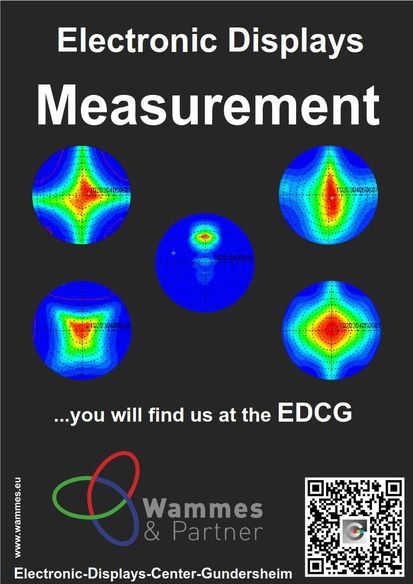

We realize very special measurement systems

We create new kinds of variable pixel structures for 2D and 3D

Analyzing and deconta- mination of Bio conta- minations like fungus, bugs and other

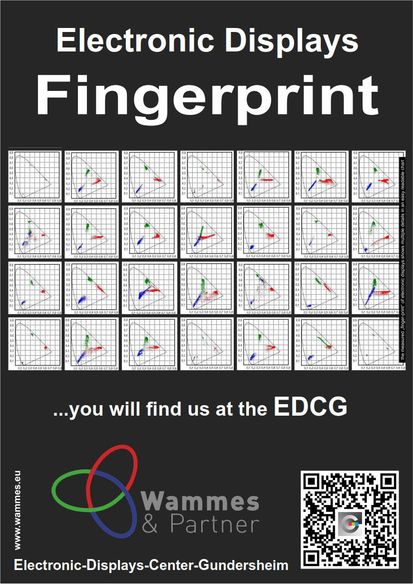

Qualifying, sorting and screening of special or dedicated display related products

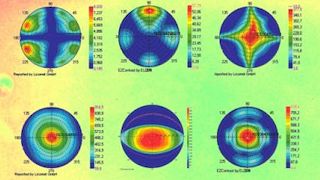

Optical measurement of displays and light sources We use Eldim equipment

Cleanroom assembly for samples and small qty, we have about 2000m² of cleanrooms

IP and solutions for advanced heat manage- ment in display related systems

Analyzing, simulating. calculating, verifying...

Power efficient light source technologies for extreme temperatures i.e. -100°C to +300°C and more

More details...-