- Optical Bonding:

The interfaces between man and machine, known as HMI, are becoming increasingly important. Devices with touch displays must therefore increasingly smarter recognize multiple touch points as well as gesture and accordingly learn to understand movements naturally and thus, correct errors automatically.

Devices with touch displays must therefore increasingly smarter recognize multiple touch points as well as gesture and accordingly learn to understand movements naturally and thus, correct errors automatically.

- Thermal Management:

As a result, the packing density of displays grows. This also increases the demands on the built-in technology, in order to protect devices from overheating, or a temporal, local or entire failure.

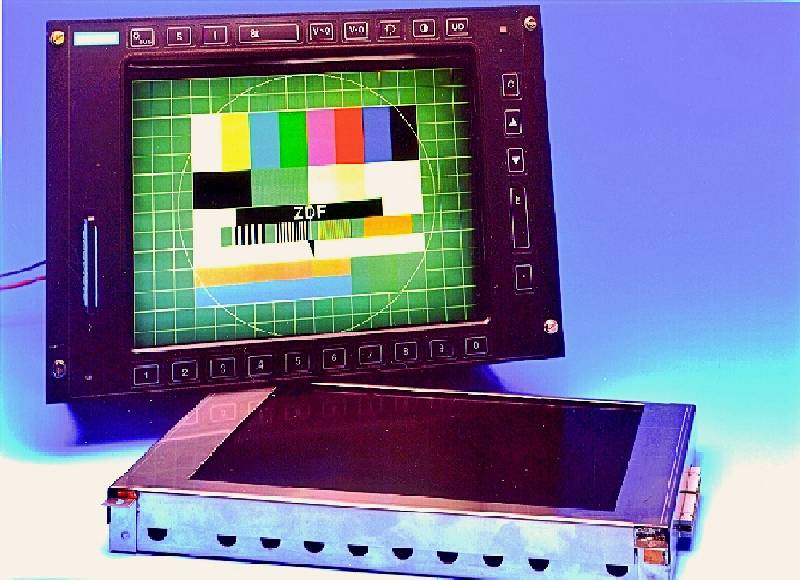

- Embedded Displays:

Displays in generall become more functional, their complexity increases. Embedded displays require an ever greater computing power, better sensors and better systems that are integrated in the display from the outset.

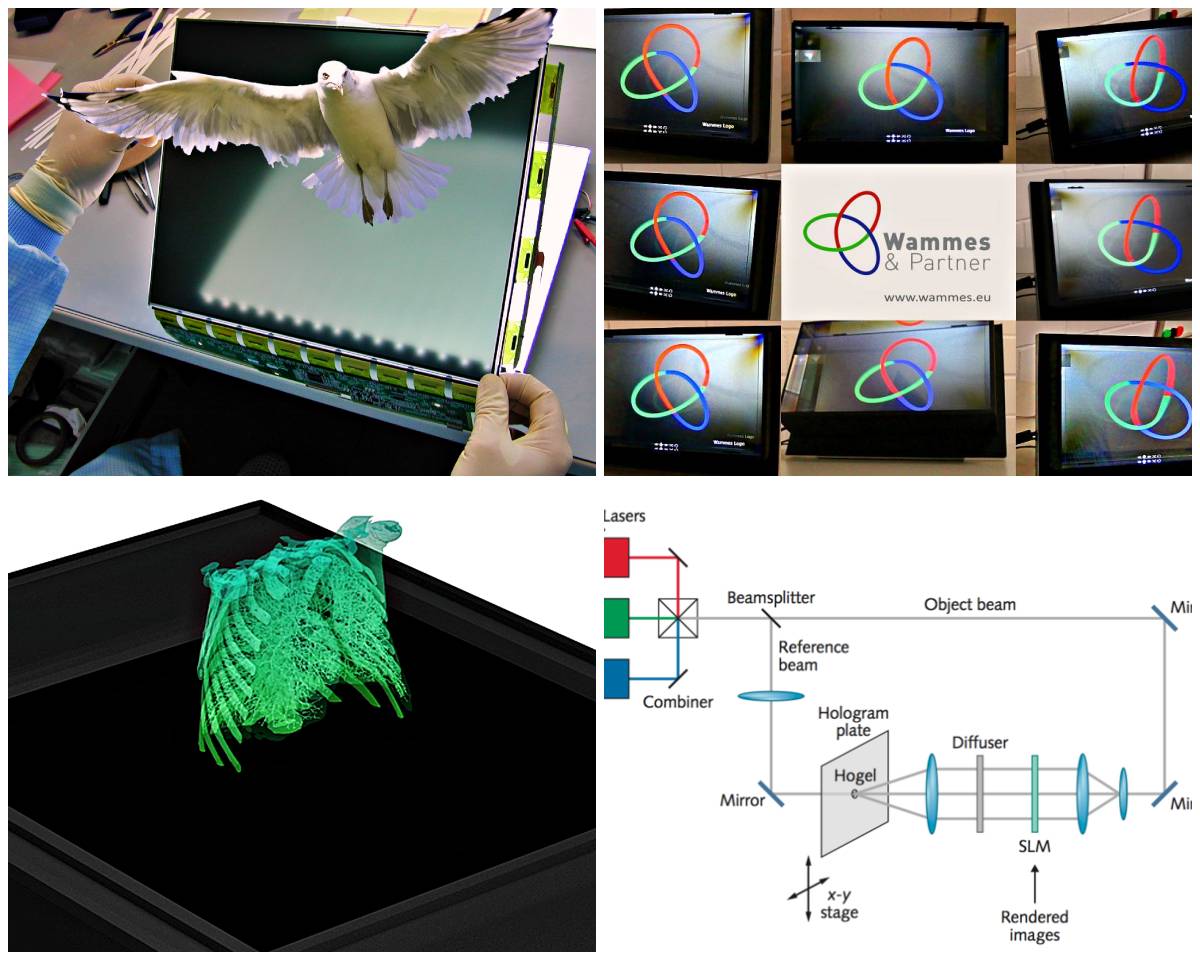

- Holography:

Our long history of development in the field of 3D displays brought us years ago to holography as a new optical "toolbox" from which you can also benefit

- Prototype construction:

Use our clean rooms, laboratories and our experienced technical staff as an extended workbench. With our large pool of tools and materials we qualify your new ideas and approaches, build them up and confirm what is feasible.

laboratories and our experienced technical staff as an extended workbench. With our large pool of tools and materials we qualify your new ideas and approaches, build them up and confirm what is feasible.

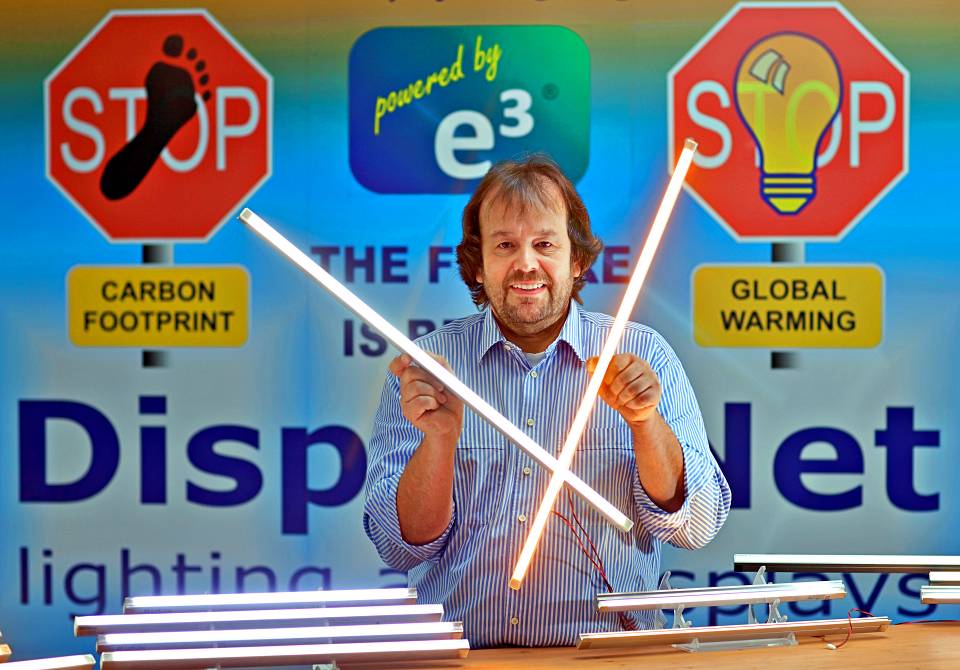

- Technical light / display backlights, special spectra - also UV:

Decades of experience with LED, CCFL and e³ light sources, lighting technology, all types of backlighting, plasma technology and the appropriate drivers - we have long been using them to bring light into the dark - but also special spectra for inspections and special applications are not new to us.

lighting technology, all types of backlighting, plasma technology and the appropriate drivers - we have long been using them to bring light into the dark - but also special spectra for inspections and special applications are not new to us.

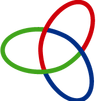

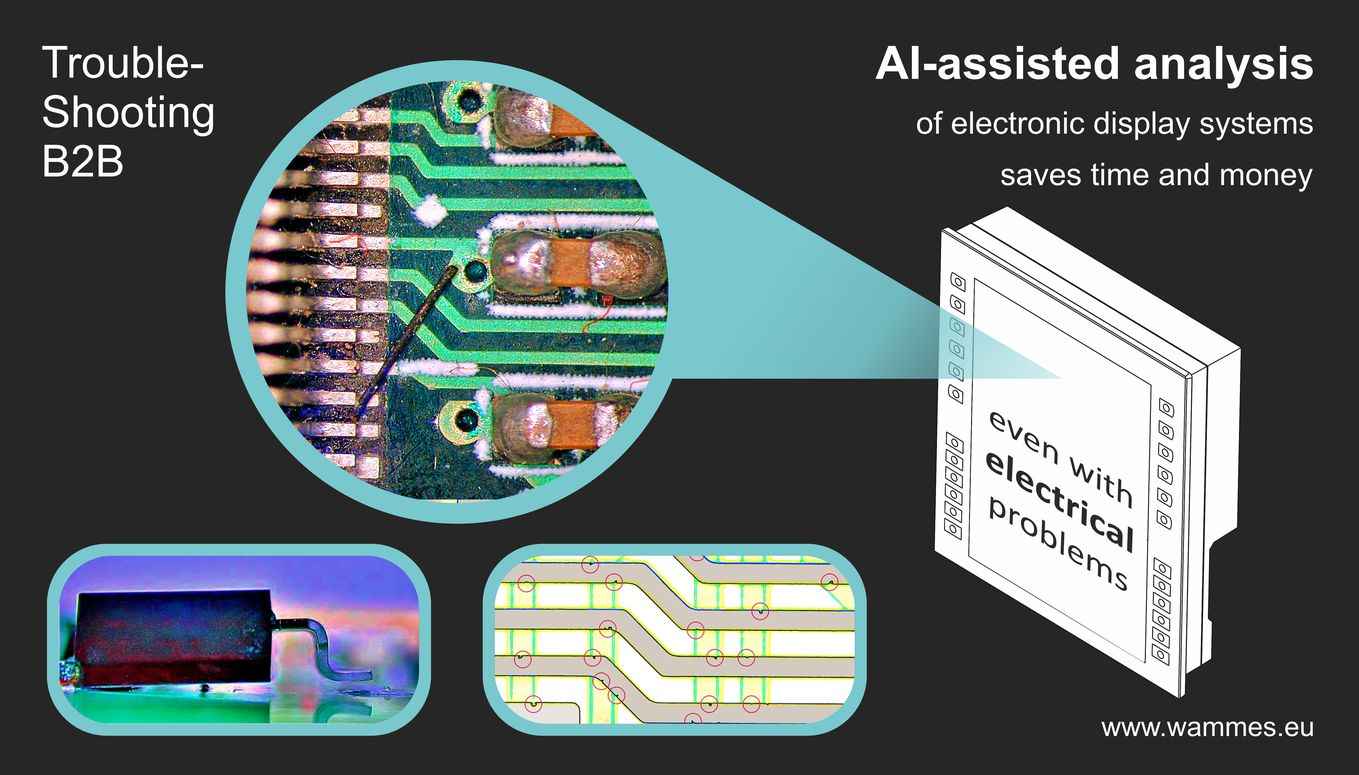

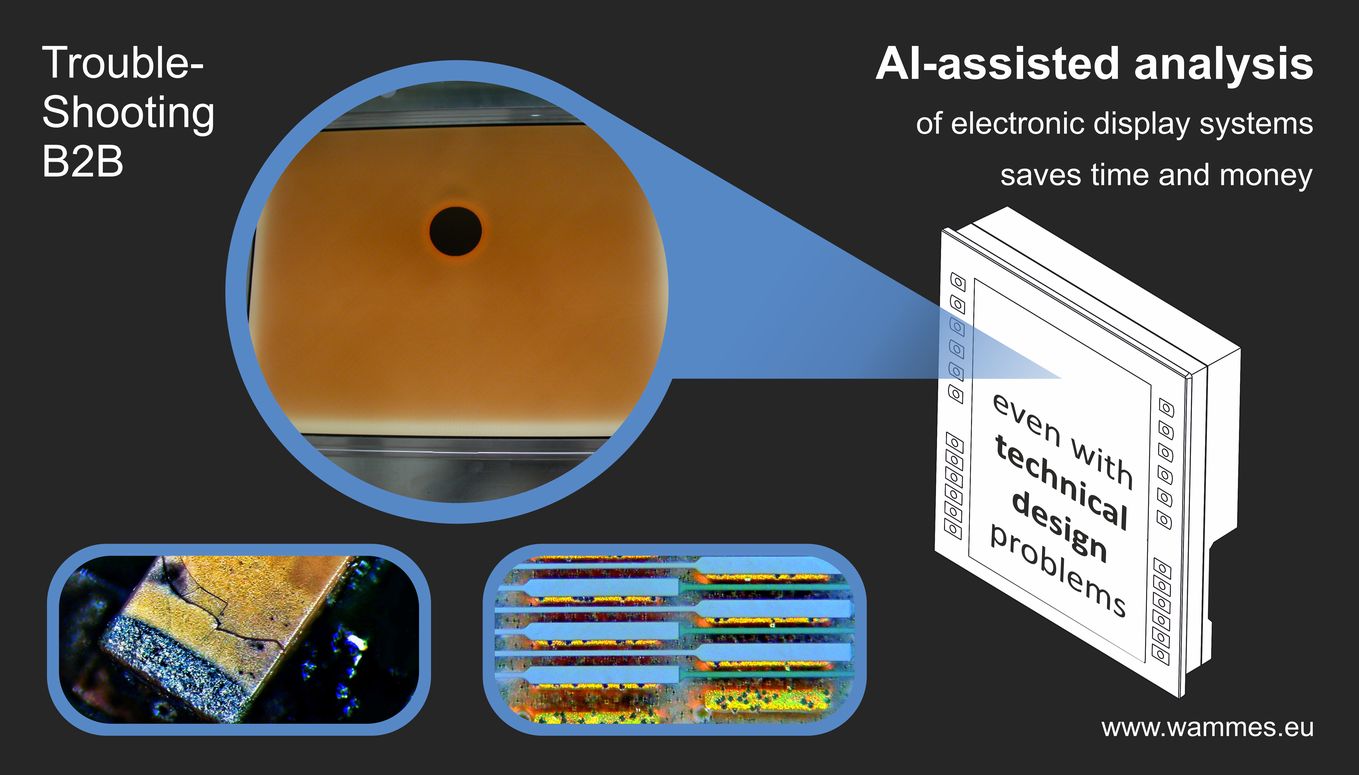

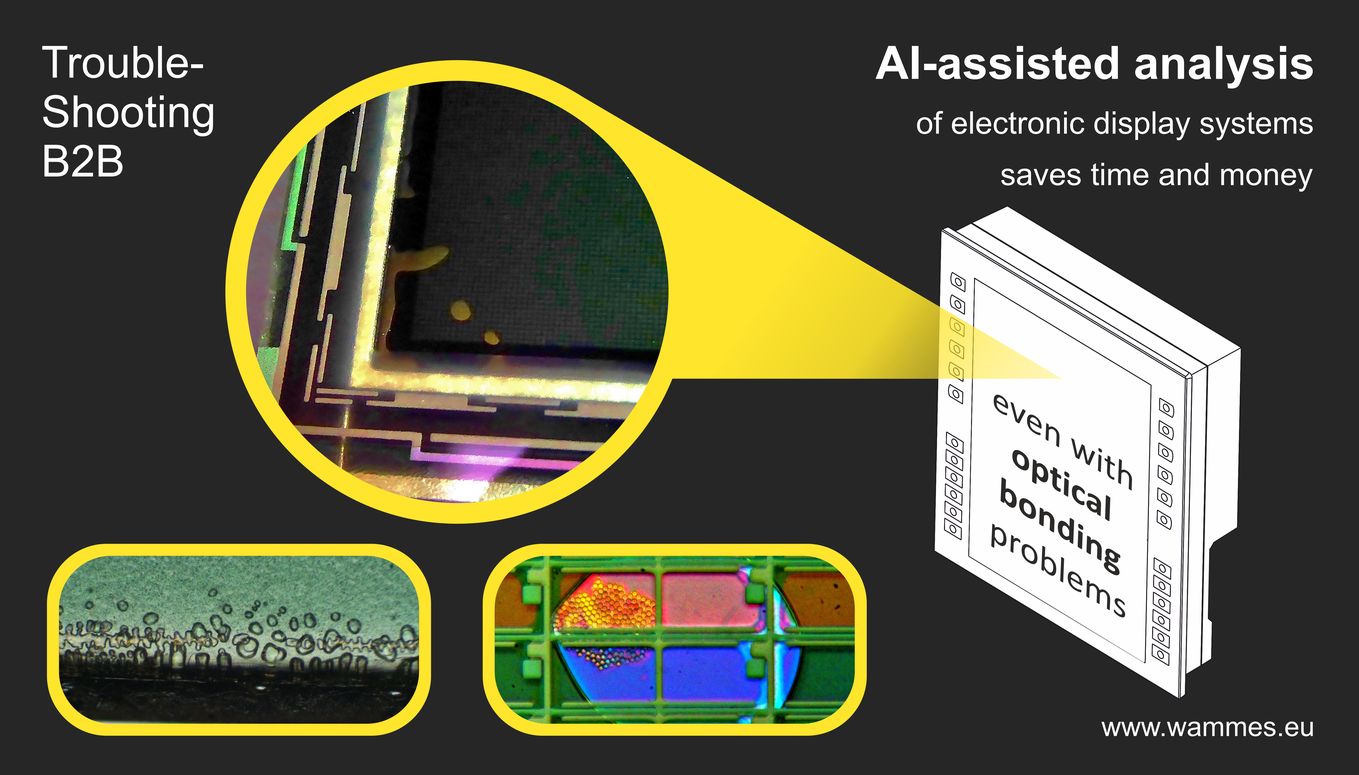

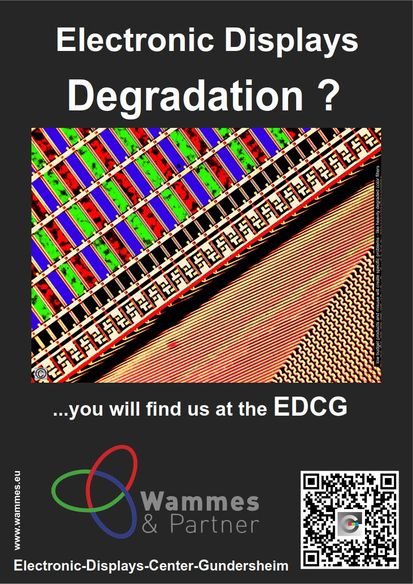

- TroubleShooting, troubleshooting and bugfixing:

"Fire brigade" missions, where the aim is to detect and solve problems now and immediately and to eliminate them for future applications, have been among the most frequently requested scientific services for several years.

- Mediation and tech. intensive training:

Not always do all parties understand the defined technical descriptions in the same way, and often there are conflicts. We help to clarify and mediate technical facts - within our main focus - in a neutral way

in the same way, and often there are conflicts. We help to clarify and mediate technical facts - within our main focus - in a neutral way

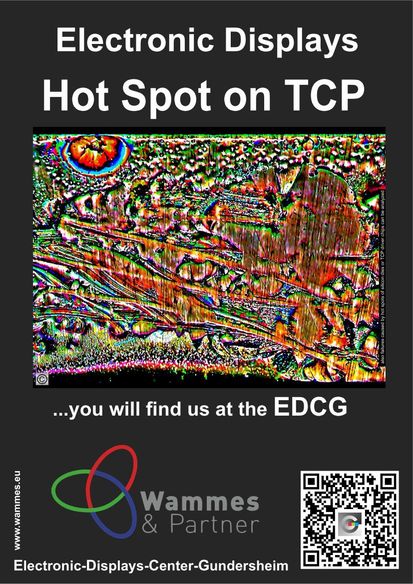

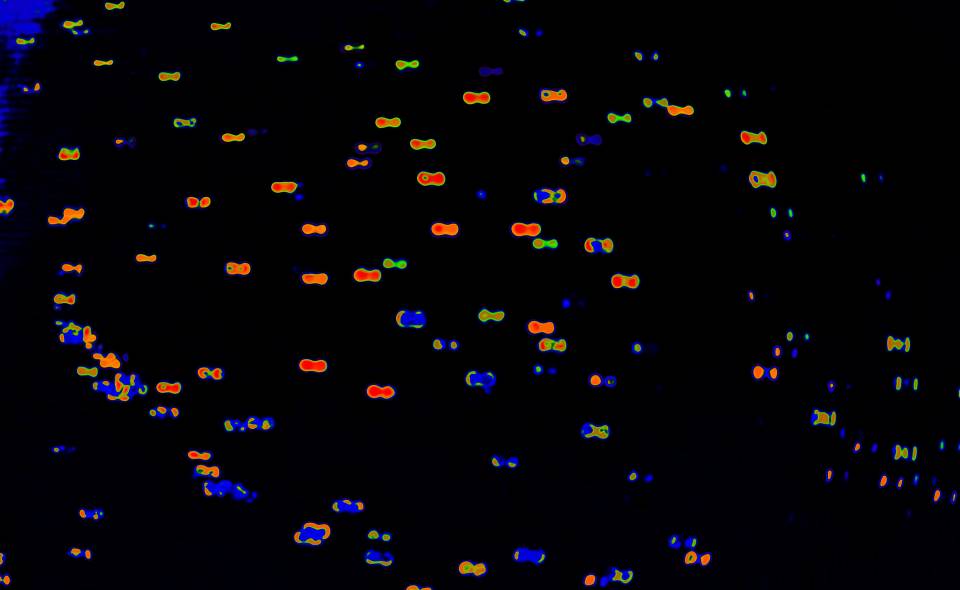

- Touch systems - and their characteristics:

Touch systems are very common - but also their peculiarities depending on different technologies from integration to control and the extremely annoying and dangerous "ghost touches" - we help to catch such "ghosts".

but also their peculiarities depending on different technologies from integration to control and the extremely annoying and dangerous "ghost touches" - we help to catch such "ghosts".

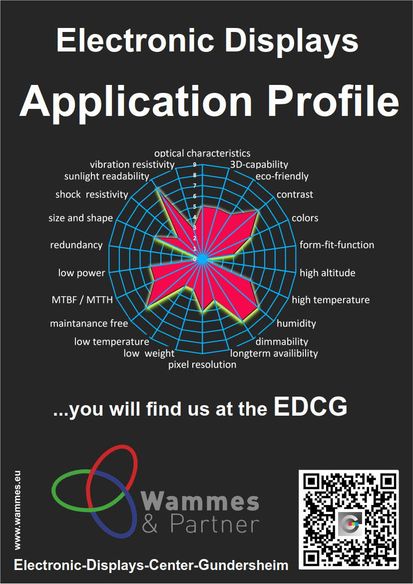

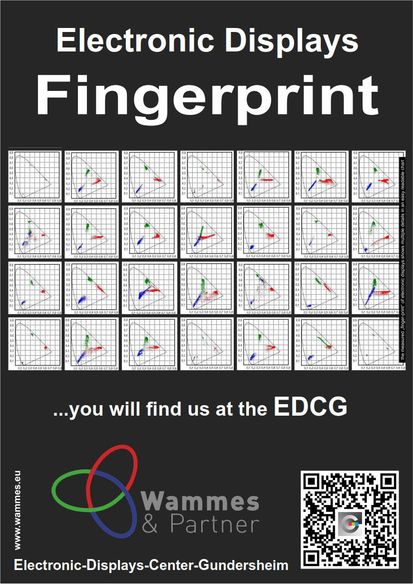

- Display fingerprint and tech. KnowHow prepared in case studies:

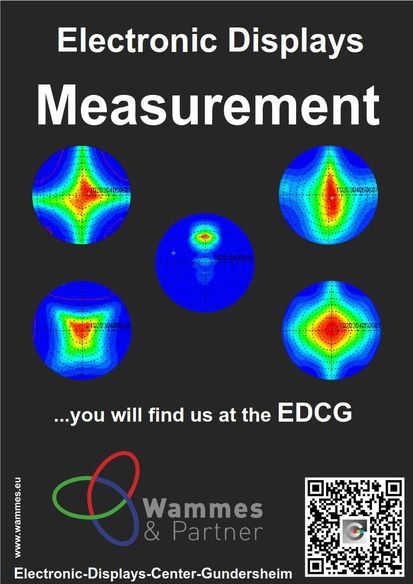

How can displays from different manufacturers or different production batches be functionally compared and evaluated in the safest and easiest way - with the display fingerprint, a metrological analysis diagram that directly discloses all details

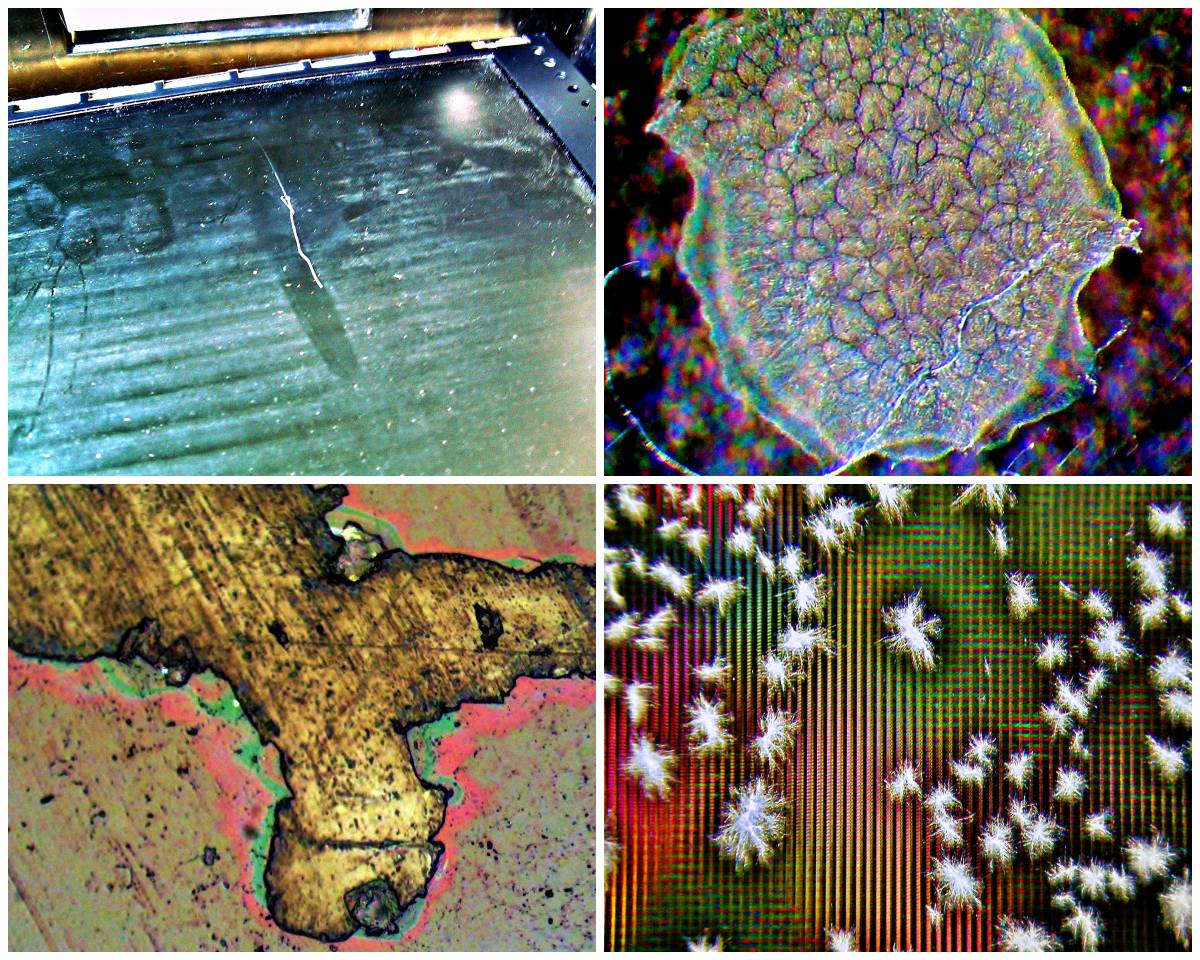

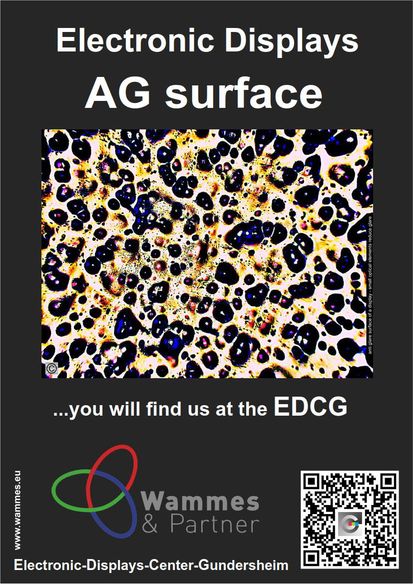

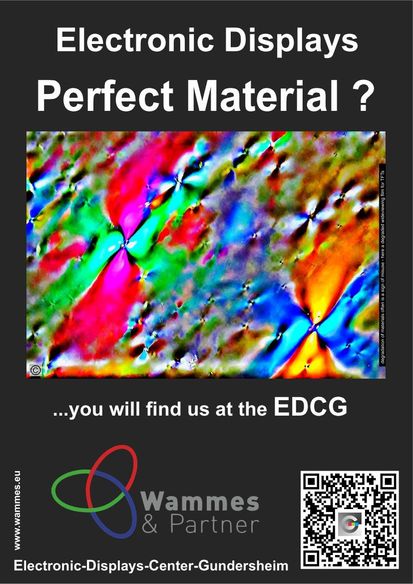

- Complex film optics and material science / material characteristics:

Displays and indicators are becoming thinner and thinner - and so are the devices in which they are used. Complex optical functions such as prisms, lenses, polarizing filters, retarders, diffusers, reflectors and other functions must therefore fit and function properly. We can help with a wide range of know-how and real foil optics.

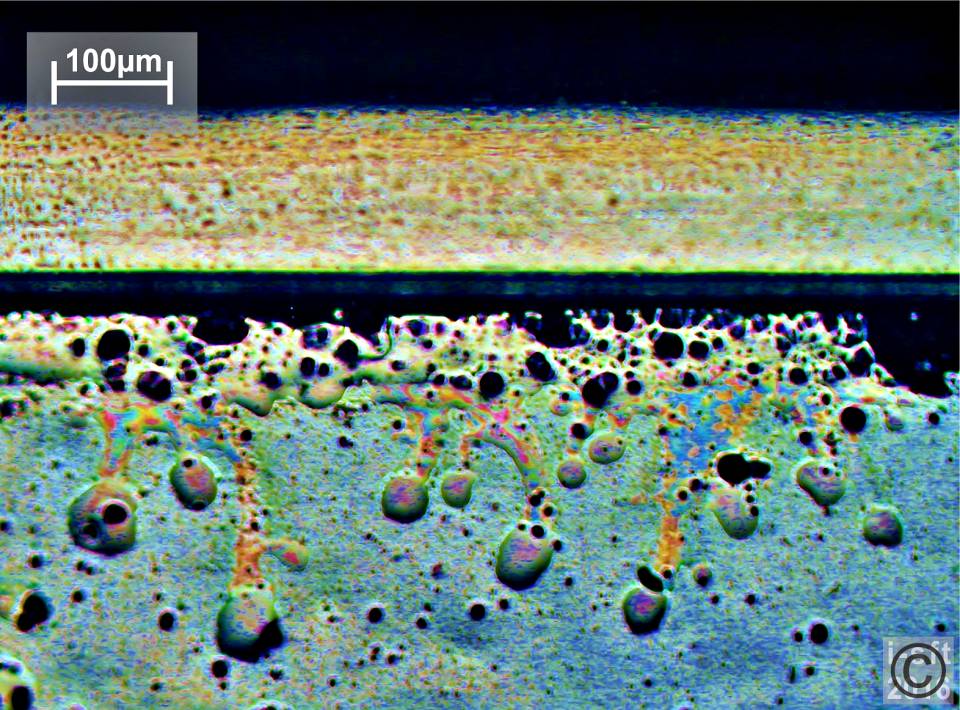

- Optical bonding and embedded systems:

The packing density of technical devices is becoming increasingly higher and therefore also requires new integration processes. An important process especially for display embedded systems is optical bonding, the crystal-clear gluing/embedding of optical functional units - with all its pitfalls. We help to adapt processes and materials to each other and analyse problems.

- Control and regulation of displays and light sources:

Modern light sources and displays don't just need "a little power" and it works - nowadays they need sensibly prepared data in order to function optimally in the system used - sounds easier than it is. We have been helping our customers to implement this successfully for around 30 years.

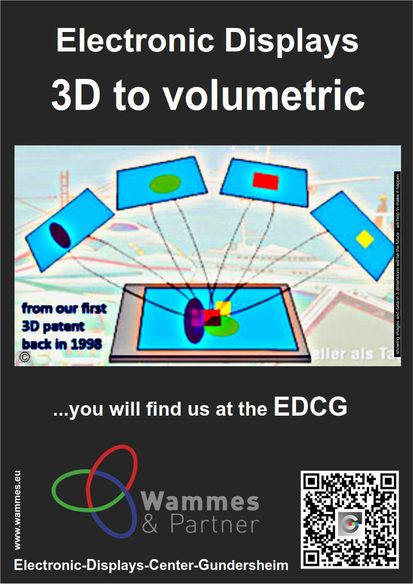

- Volumetric Presentation:

Also 3D capability will be an increasingly important area of display technology. Thus, it can entirely become accepted, it requires a thoughtful advancement in accordance with physical processes.

- Optical measurement services (displays & technical lighting):

Understanding and analyzing the problems around the display by means of macroscopic and microscopic examination are part of our daily business and are the cornerstones for the development of various methods of solution.

the problems around the display by means of macroscopic and microscopic examination are part of our daily business and are the cornerstones for the development of various methods of solution.

- Trainings, workshops, expertise, expertises and education:

We support you in technical matters and pass on our know-how in order to avoid future problems, optimize processes and understand technical and physical relationships.We bring your qualified employees up to date and provide expertises and reports. Use our knowledge database.

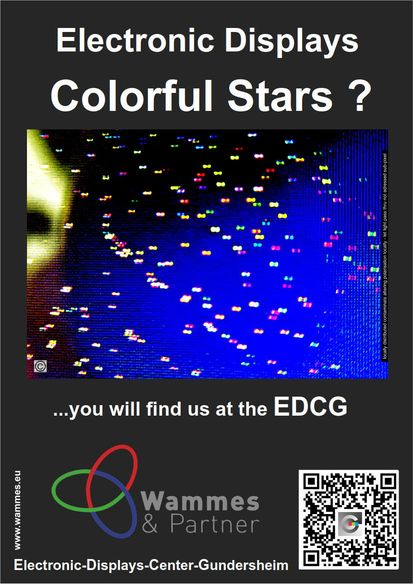

- Understand display effects: MURA, Flicker, After Imaging and many more:

Mura or clouding generally refers to a non-uniform display, after imaging describes parasitic changes of the displayed image content, flicker does not only occur in the display...We analyse and understand the complexity and the multitude of effects that occur in this context and can support you accordingly in eliminating and avoiding errors.

after imaging describes parasitic changes of the displayed image content, flicker does not only occur in the display...We analyse and understand the complexity and the multitude of effects that occur in this context and can support you accordingly in eliminating and avoiding errors.

- Stress test and error provocation:

Shock, vibration, climate, high voltage - we have the technical equipment to bring your products to the technical stress limit.

- Technical analysis and microscopy:

Not always everything works "by itself" as desired - often it is hidden in the "last corners" - with our detailed tech. analyses and sophisticated microscopy technology, we also help to track down the last hiding place.

- Customized electronic displays:

Use our clean rooms, laboratories and our experienced technical staff as an extended workbench. Together with our well-networked partners, we can also make customized displays a reality.

laboratories and our experienced technical staff as an extended workbench. Together with our well-networked partners, we can also make customized displays a reality.

- System integration, thermal management and "total cost of ownership":

Combining assemblies to finished devices sounds easier than it really is. In the rarest case it works like "LEGO", because here the single assemblies do not really "know" each other and often "rub" against one another. We help to get stable systems, which will work without problems for a long time.

- Obsolescence supply:

Especially in such particular times as these, one is not immune to surprising product discontinuations - obsolescence supply is easiest to achieve in a large network and thus addressable, widely different stocks

one is not immune to surprising product discontinuations - obsolescence supply is easiest to achieve in a large network and thus addressable, widely different stocks

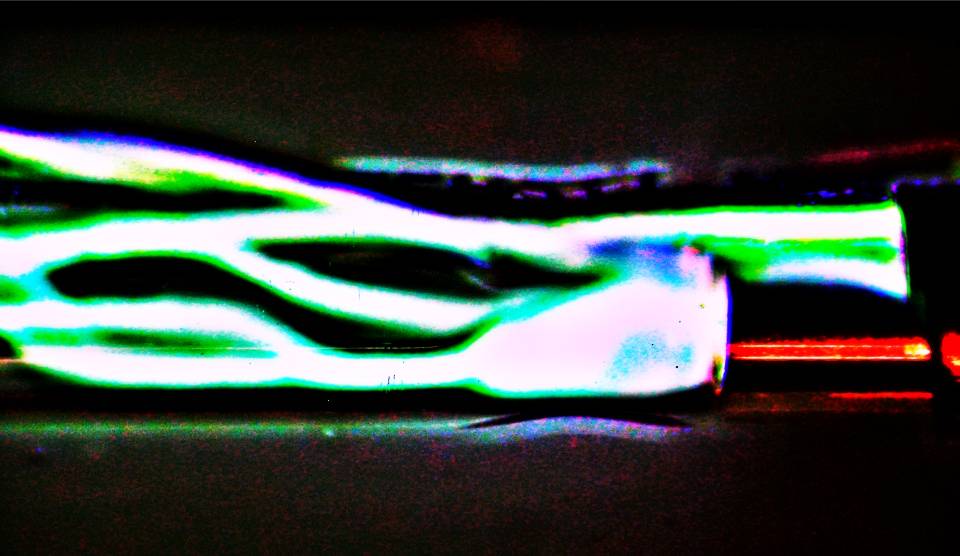

- Plasma processes (atmospheric plasma to ultra-high vacuum):

The use of plasma processes can be heard more and more often with critical high-tech products - rightly so - plasma processes enable functionalities and properties that are otherwise not achievable, but there are extremely many parameters to consider - we can help and implement

critical high-tech products - rightly so - plasma processes enable functionalities and properties that are otherwise not achievable, but there are extremely many parameters to consider - we can help and implement

- Feasibility studies and "carbon footprint":

New ideas have to prove their suitability, ideally with a lower carbon footprint than their predecessors. Proving - or even burying - new ideas is important for further developments in any technology. We help to implement and verify what physics allows.

ideally with a lower carbon footprint than their predecessors. Proving - or even burying - new ideas is important for further developments in any technology. We help to implement and verify what physics allows.

- Evaluation of tech. specifications and high voltages in miniaturized systems:

To understand technical specifications correctly and to recognize completely what is really in there and what is not - and also what effects does it have - or not. Admittedly difficult and time-consuming, but fundamentally necessary. We can help!