When touch becomes more

Adapted coatings have their right to exist. However, there are mutual dependencies between system and components.

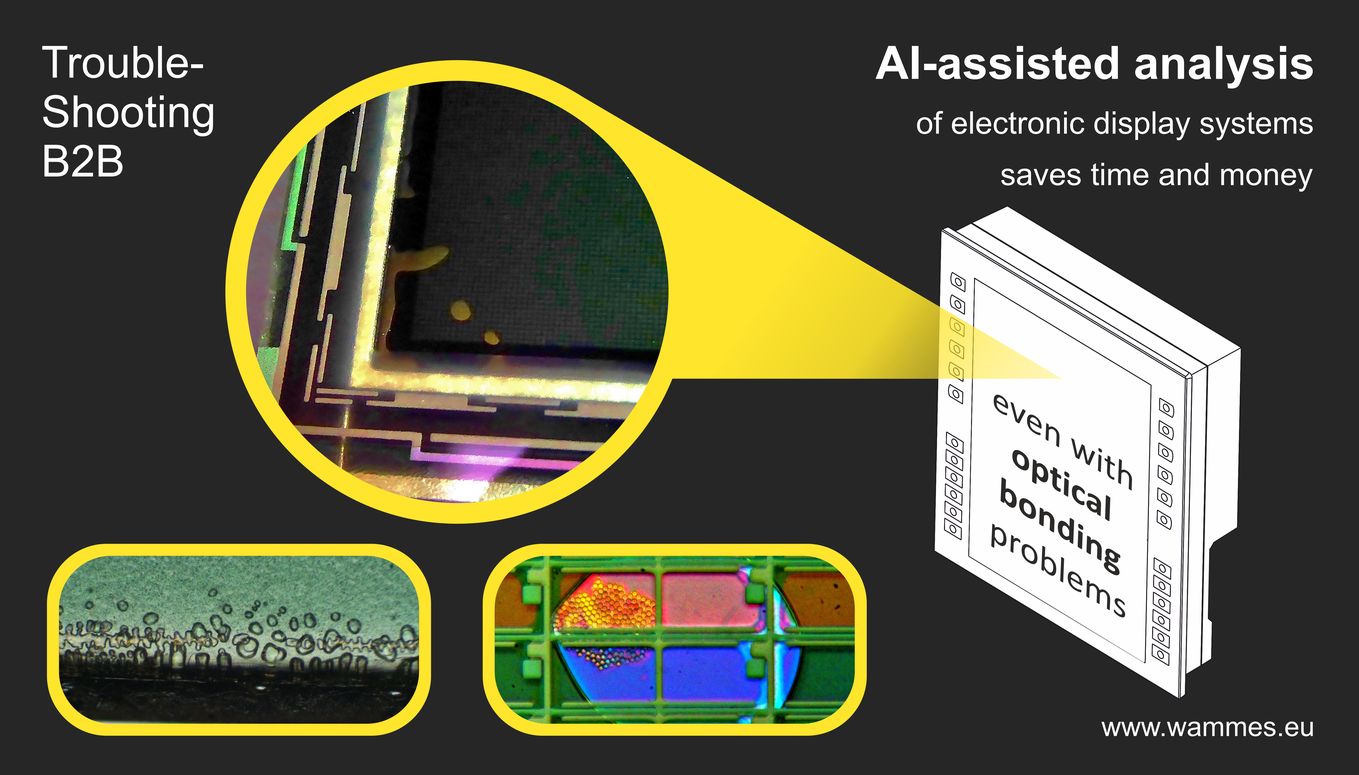

What is seldom considered with coated touch displays

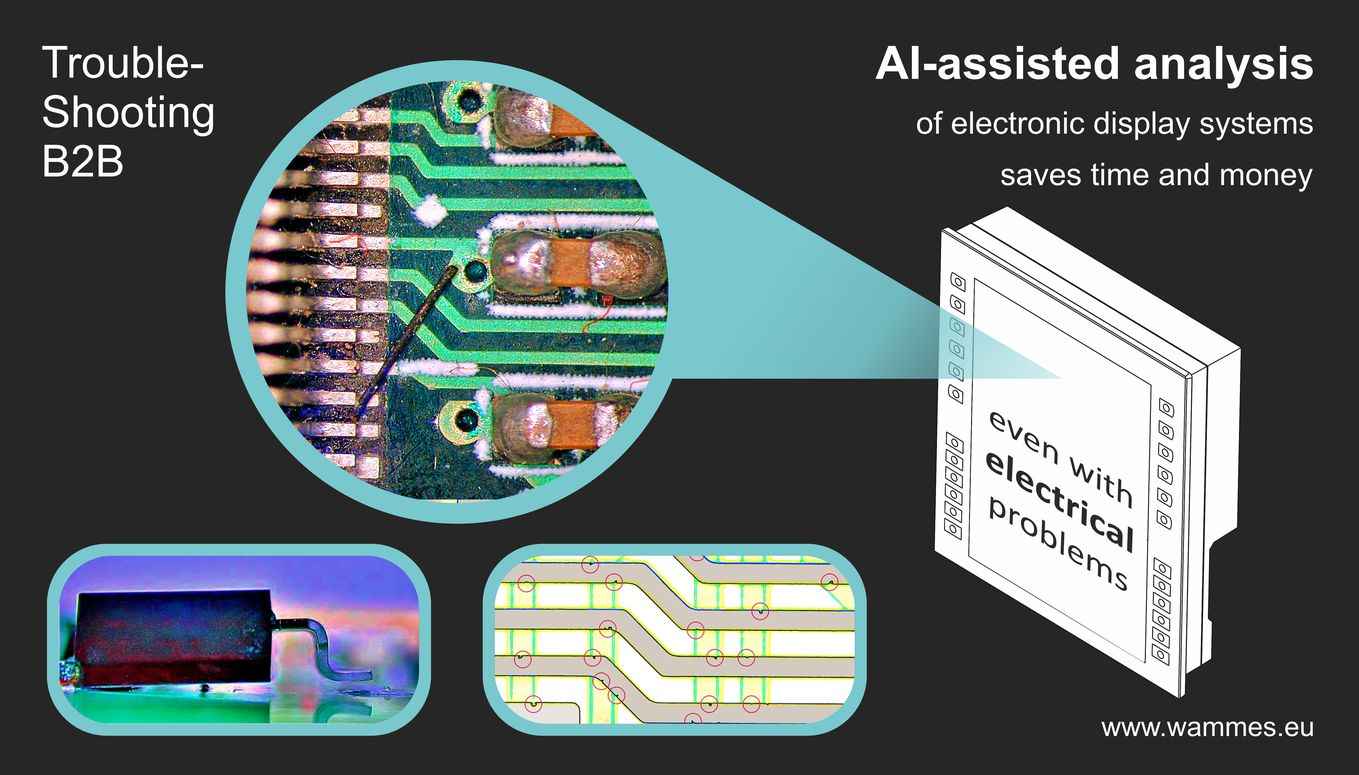

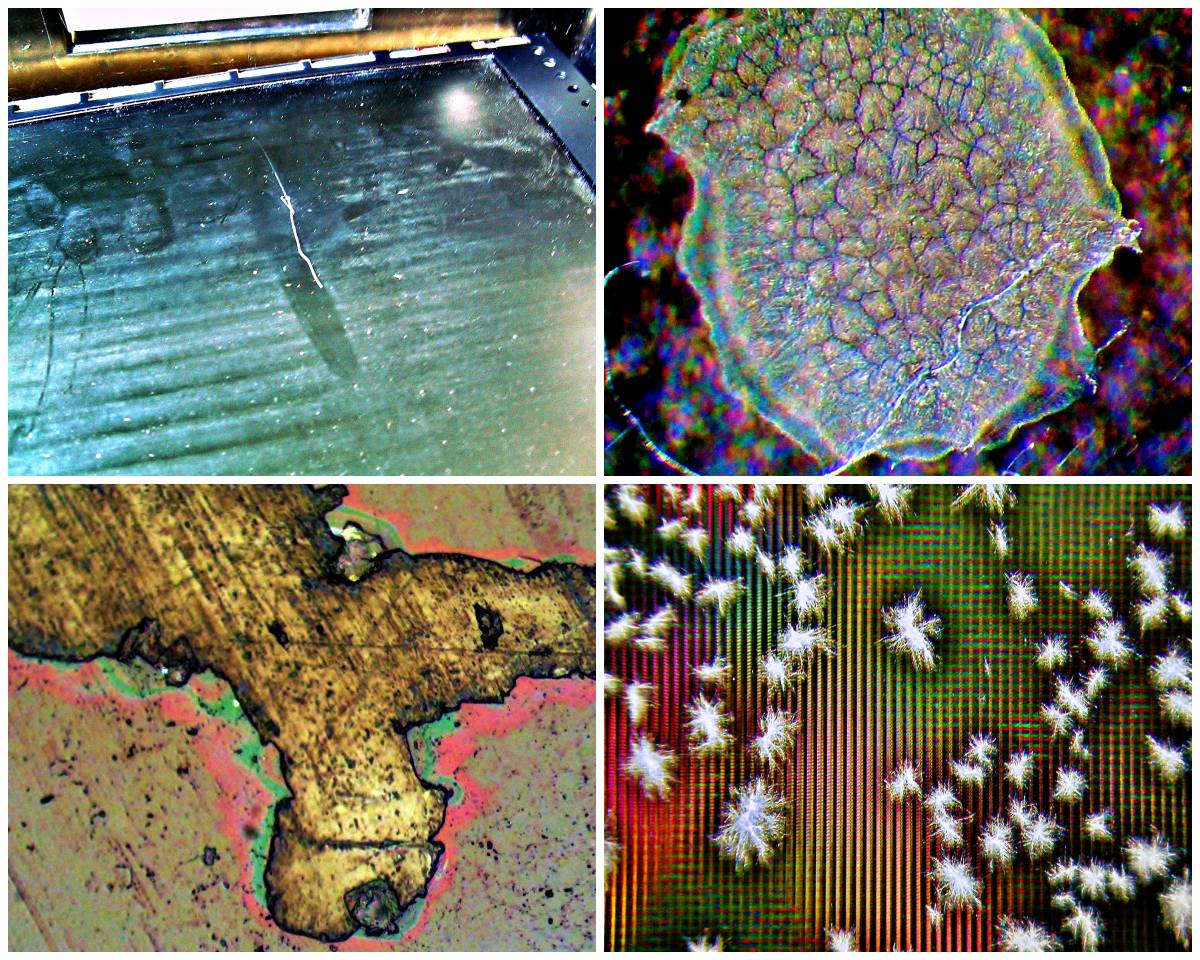

Touch displays are exposed to very different influences in different industries: Dust, water and dirt, which are produced during manufacturing processes, can scratch the display or even make it completely unusable. In humid environments, mould can develop inside. Adapted functional coatings therefore have an undisputed right to exist. They not only make displays more robust and less susceptible to external influences and vandalism. Under certain circumstances they also protect against disease. In medicine, for example, when many fingers are working on the same device. But a coating alone is not enough. New dependencies between system and components arise, which have to be reassessed in their entirety.

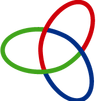

This is because the combination of installed elements must be re-evaluated and implemented accordingly with every change. Replacing parts according to the motto "old to new" is not possible without further ado. This already applies to uncoated displays. For example, old materials such as ITO ceramics are still used for curved or even flexible displays or their components. The ITO (Indium Tin Oxide) layer is indeed the current state of the art for inexpensive and transparent conductive structures. However, it is also brittle and therefore unsuitable for such applications. Alternatives such as silver or carbon nanotubes have their own properties. However, especially with additional display coatings, both inside and outside, misinterpretations can occur if the evaluating algorithm can no longer understand what the user wants by touch. Sure, with tablets, smartphones and other commodity displays or systems this would not have any really dramatic consequences. In industrial applications, wrong commands can differentiate worlds.

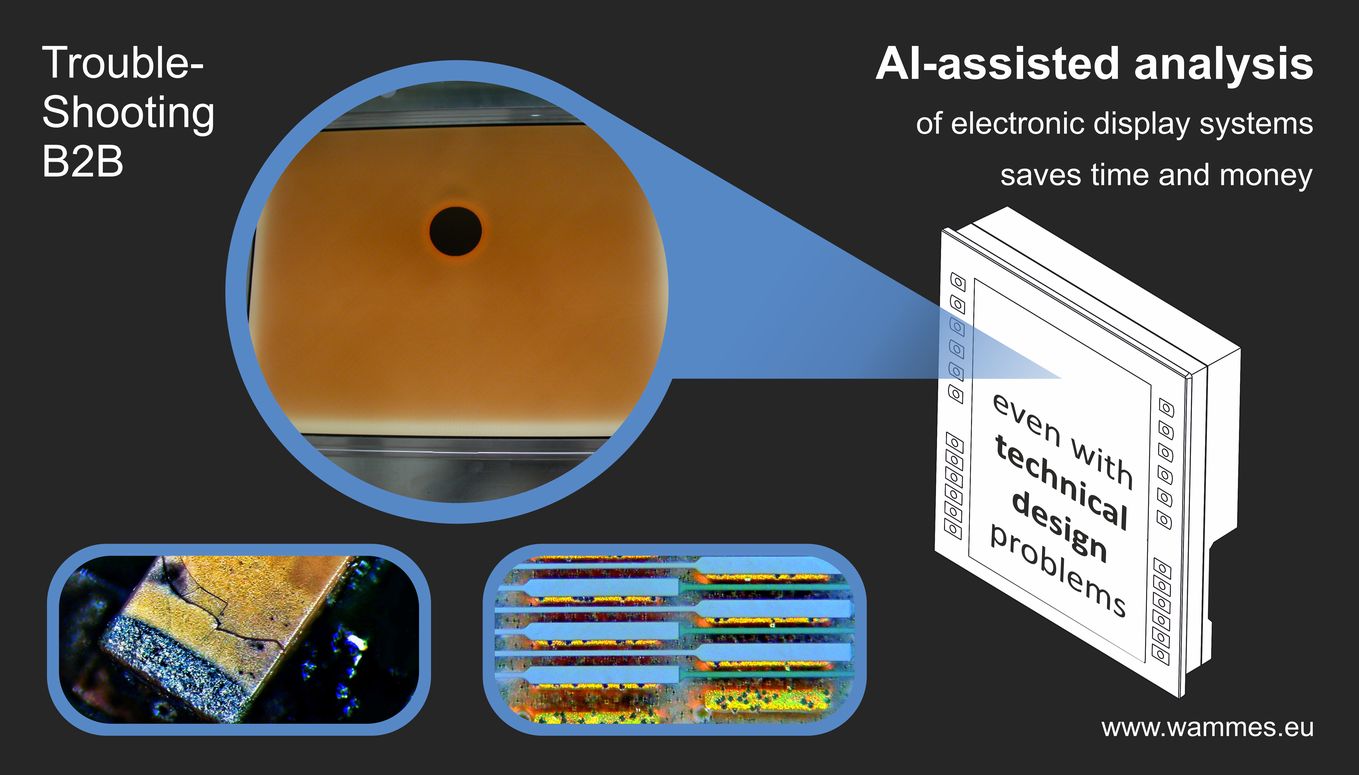

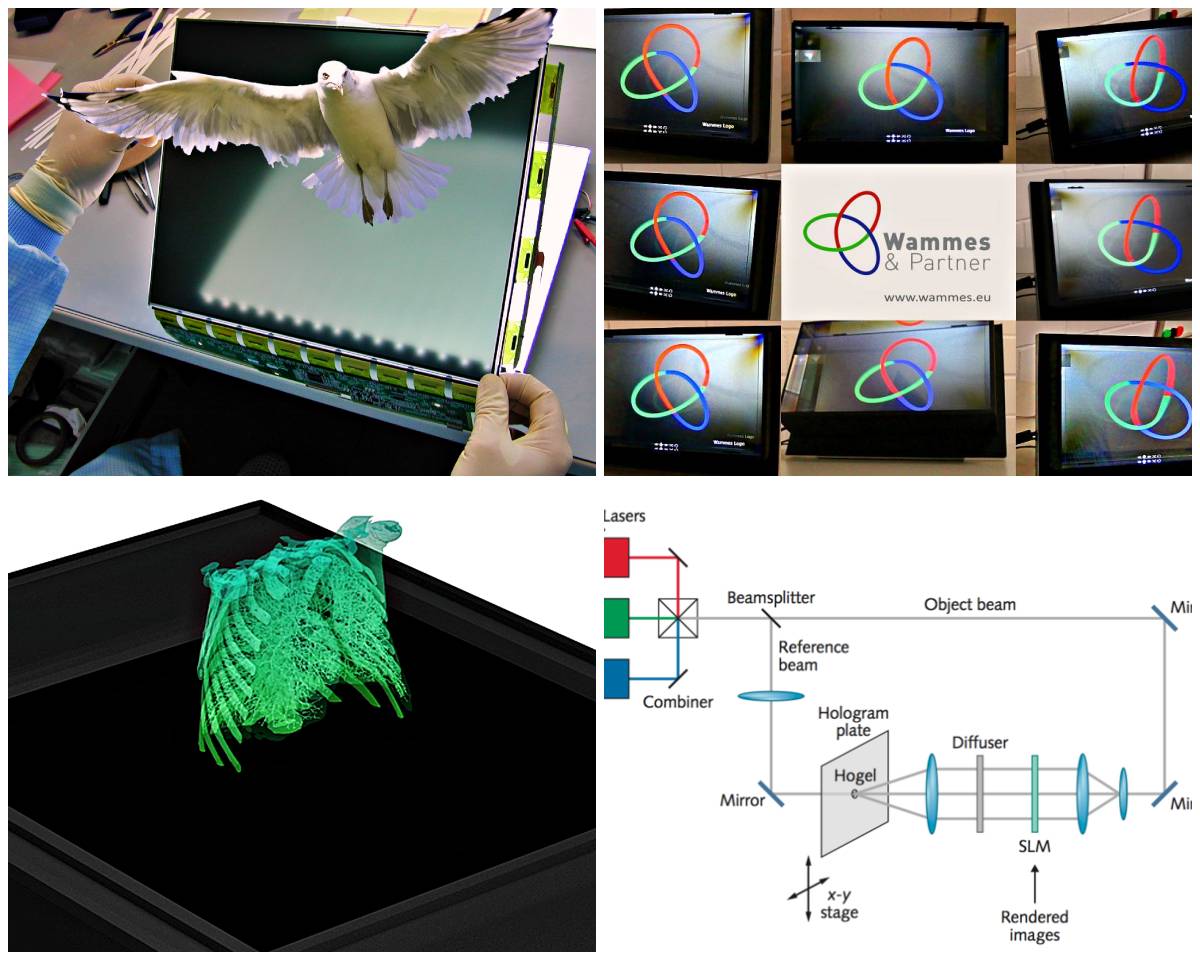

From interactions and too many touches

A widespread misconception in the industry is that PCAP (projected capacitive) is a synonym for touch displays. This is simply wrong. Manufacturers must move away from the idea that simply implementing a common term can actually satisfy all parties involved. PCAP is a method description and not a finished, firmly defined product, i.e. on balance a technical configuration. It does indeed have an advantage over resistive sensors because it is inherently less susceptible to vandalism. However, it is precisely this supposed panacea that needs to be re-initialized, calibrated or updated after an additional coating, depending on the application and manufacturer. In more abstract terms, the interaction can be compared to a car: If the windows are replaced by bulletproof glass, shock absorbers, brakes, etc. must also be adapted.

The central problem for coated displays is sometimes the external influences on them: permanent vibrations, electric fields or even electromagnetic radiation and unstable mass concepts. The algorithm in the microcontroller, the brain among the built-in components, must therefore be able to recognize whether a command comes from a touch or whether interference factors are shifting the charges. The higher the artificial intelligence, the better and safer the touch sensor. It therefore helps to know how many touches or shifts in charge have to be detected and evaluated simultaneously. In tactical or gaming applications, algorithms must be able to detect up to 50 touches simultaneously. In contrast, ordinary display applications only need to be able to calculate two touches simultaneously: for selecting, wiping, rotating and zooming.

Algorithms are dependent on "brainware" and computing power: The more touches have to be detected, calculated and implemented, the longer the process takes. In order to actually execute the command in the given latency time, smart algorithms are of course provided with more micro-controller performance. Depending on the sector and industry, this is relevant to safety. Of course, it is also possible to program algorithms as drivers and, for example, outsource them to powerful external GPUs. However, small, inexpensive, preprogrammed and directly integrated chips are often used, although they are usually not easily updatable. Meanwhile, easily updatable solutions are easier to replace or adapt to the required computing power and function. However, this results in more interfaces and thus higher costs and more complex qualification activities. Ultimately, the required fault tolerance for the system is the decisive factor here as well: depending on the safety relevance and the expected requirements, the suitability of the system.