Immaculate Conception

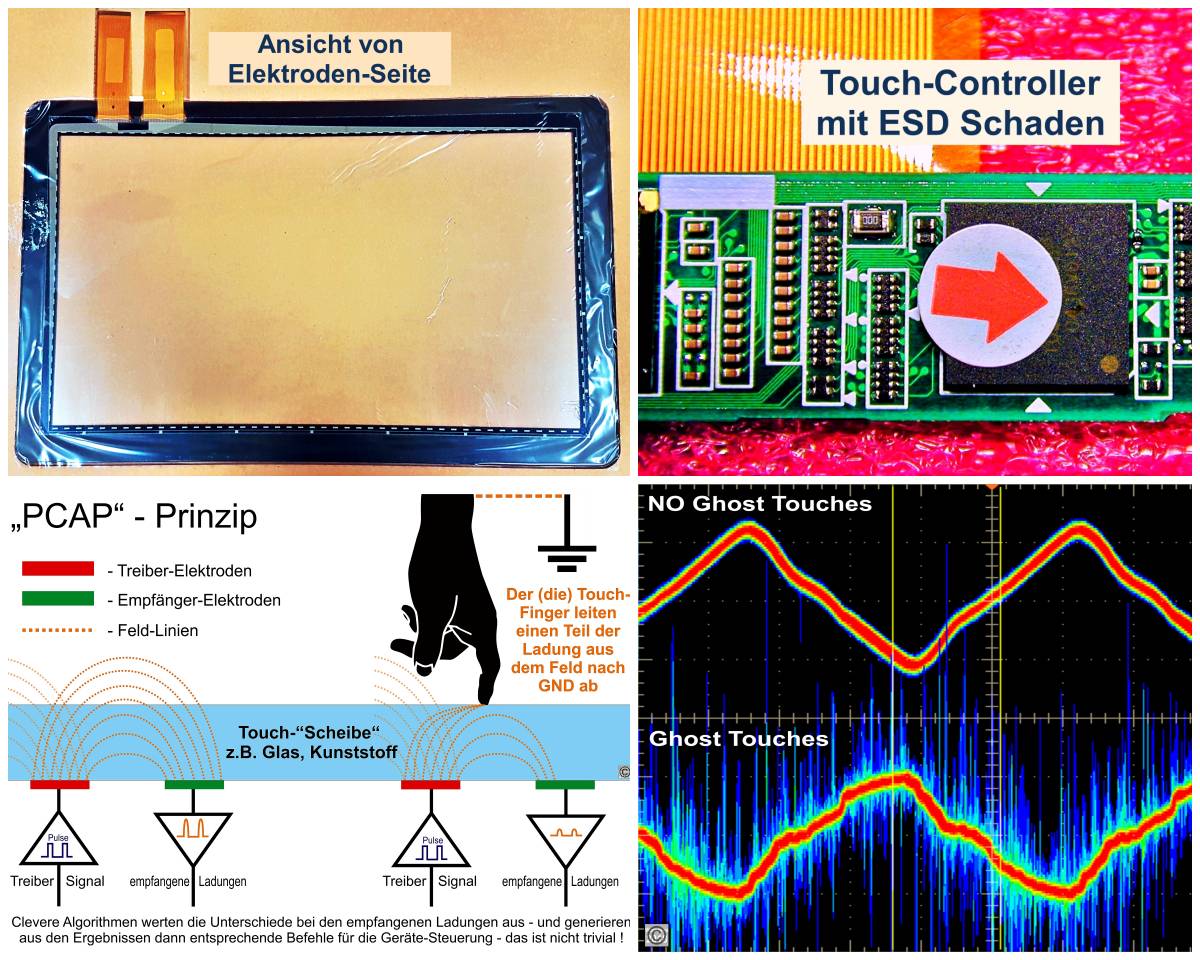

PCT displays are no longer based on mechanical but electrical detection. However, this also creates new sources of error, which can only be eliminated by an adaptive algorithm.

Electromechanical touchscreens: of outdated ideas and new possibilities

The touchscreens installed today have little to do with electromechanics. In operation are solid-state solutions based on PCT (Projected Capacitive Touch), which do not require any actual mechanical input. Nevertheless, there are discrepancies on the part of the manufacturers: On the one hand, PCT displays are to be installed, while on the other hand the specifications still contain requirements for electromechanical solutions. The differences lie both in the design and in the technical handling. So solid-state solutions are much more robust. However, new errors are emerging, such as the ghost touch, where the algorithm of the display comes to a prompt like the virgin to the child - without touch. The greatest challenges of modern touch systems are therefore to detect whether there is actually an intention to operate and, if so, to report back immediately to the operator that the command has been recognized.

Until not so long ago, touchscreens were mechanical. An operator pressed the display. The mechanical resistance was thus also the feedback that the command had reached the device. Detection was usually capacitive or resistive, i.e. either by changing the distance between capacitors or - to put it simply - by pressing the contacts together. Others worked with force sensors in the corners of usually larger panes of glass or protective glass, whose contact was detected with them. Still others used infrared grids, which clamped a grid light barrier in front of the display, which recognized the command by interrupting it accordingly. Almost all older generations of touch systems, however, were always operated by force or at least by path detection. For mechanical reasons it was always guaranteed that an intended electrical impulse was electronically processed. An action resulted in a direct reaction.

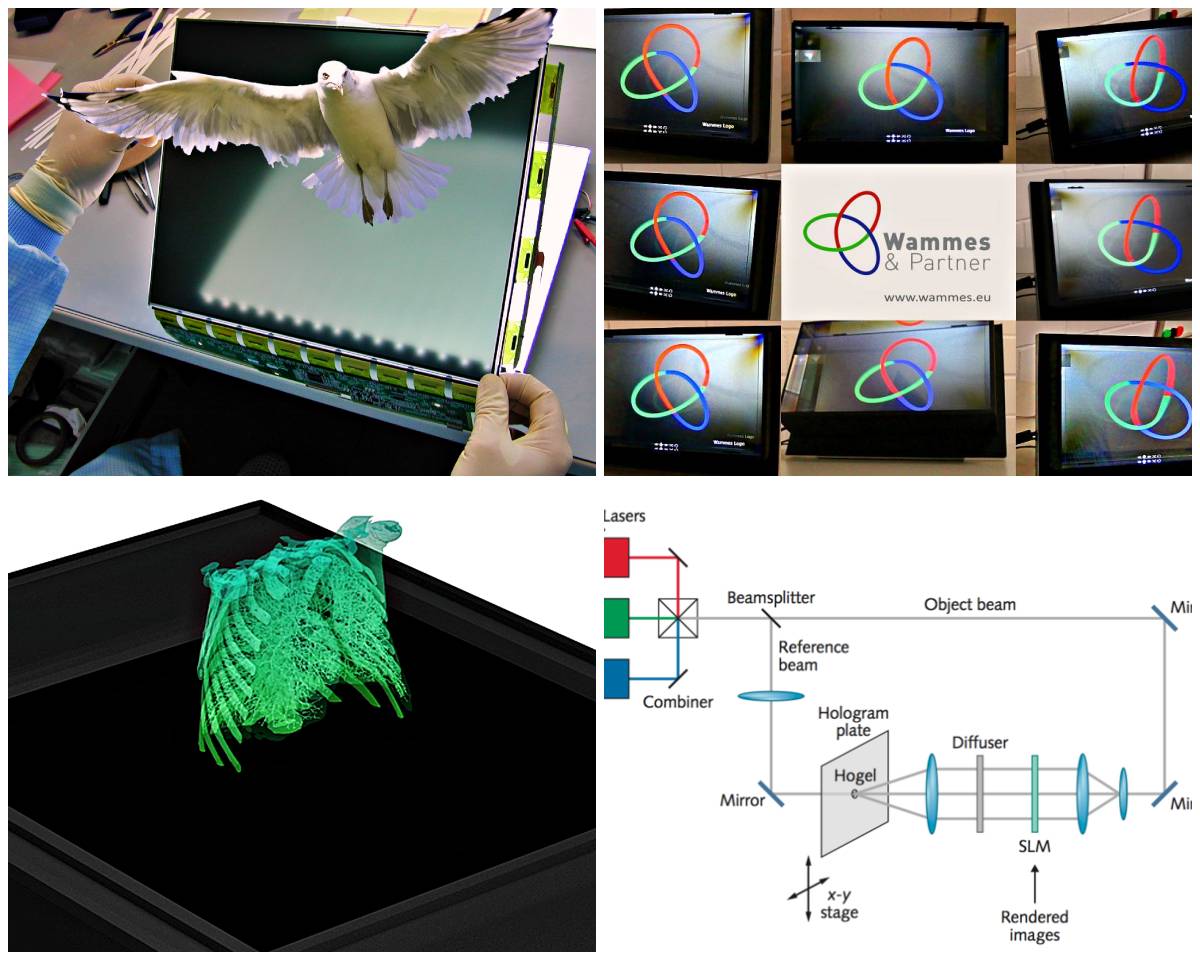

Non-touch display

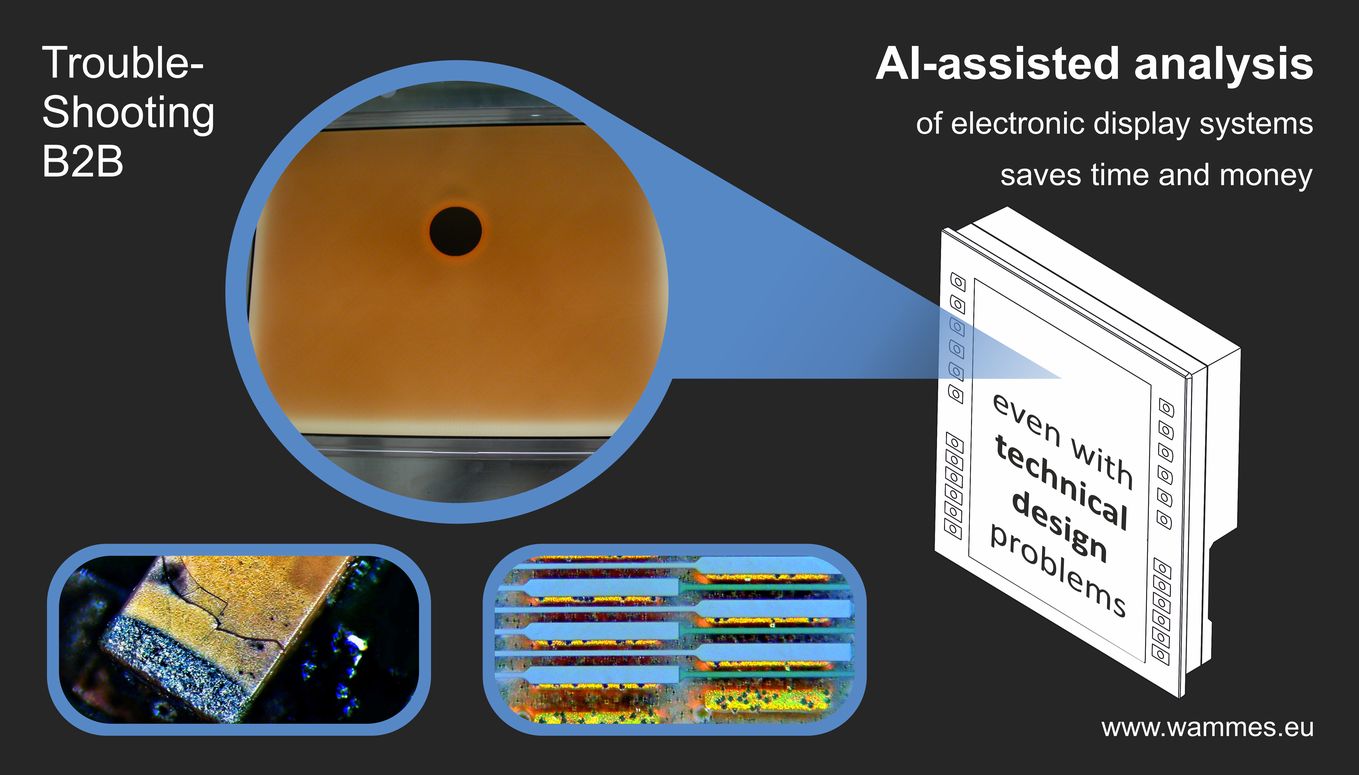

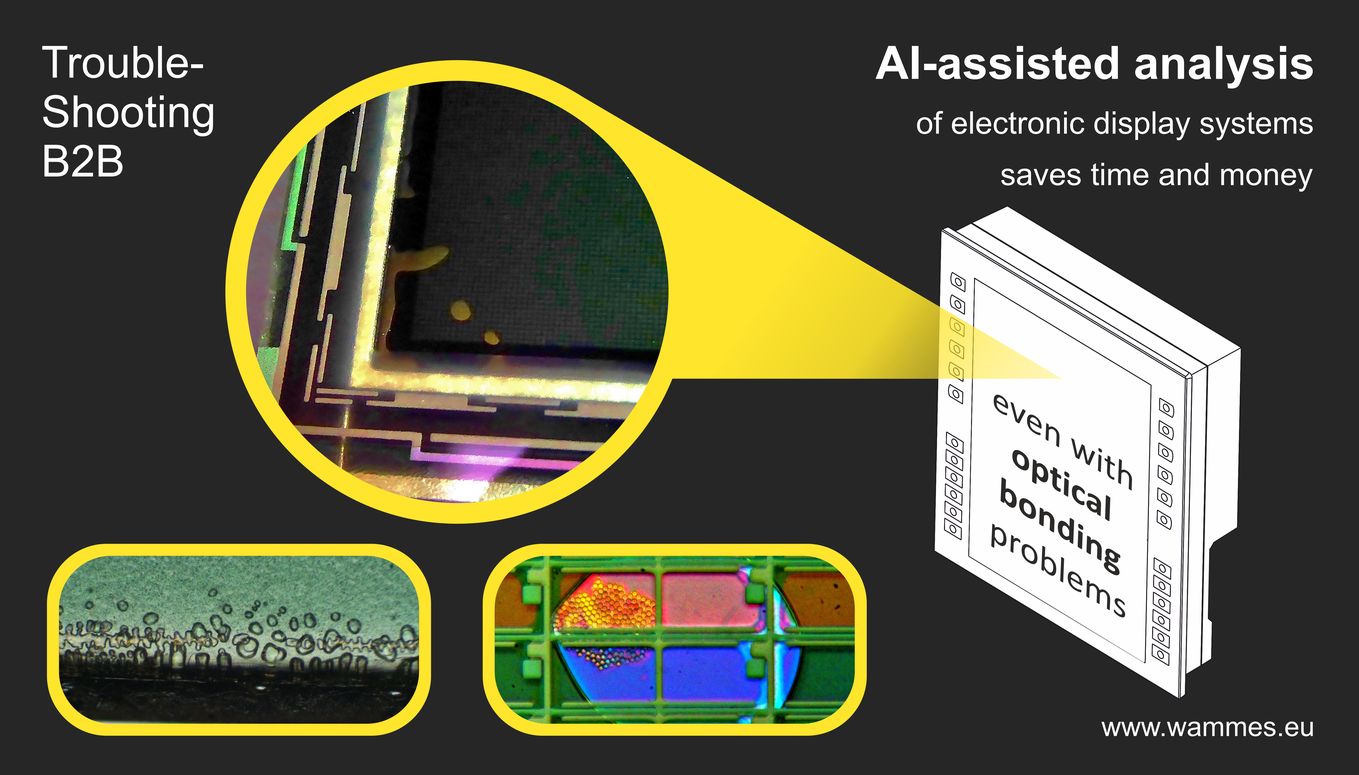

With current generations, especially with PCT, this direct connection no longer exists. A matrix or grid of small transmitters, which constantly generate electric fields, is distributed over their surface. In their immediate vicinity are receivers that directly evaluate these signals. The permanent flow of information is, so to speak, the idle state of these touch systems. This decouples the touch request from the electromechanics: It is not a mechanical process that triggers a detection, but the disturbance of this communication. Seen in this light, there is no longer any need for real touching on new touch systems. This is made possible by artificial intelligence, which detects faults on the basis of defined parameters, derived orders of magnitude or variants. For example, if a certain minimum area or number of transmitters is affected.

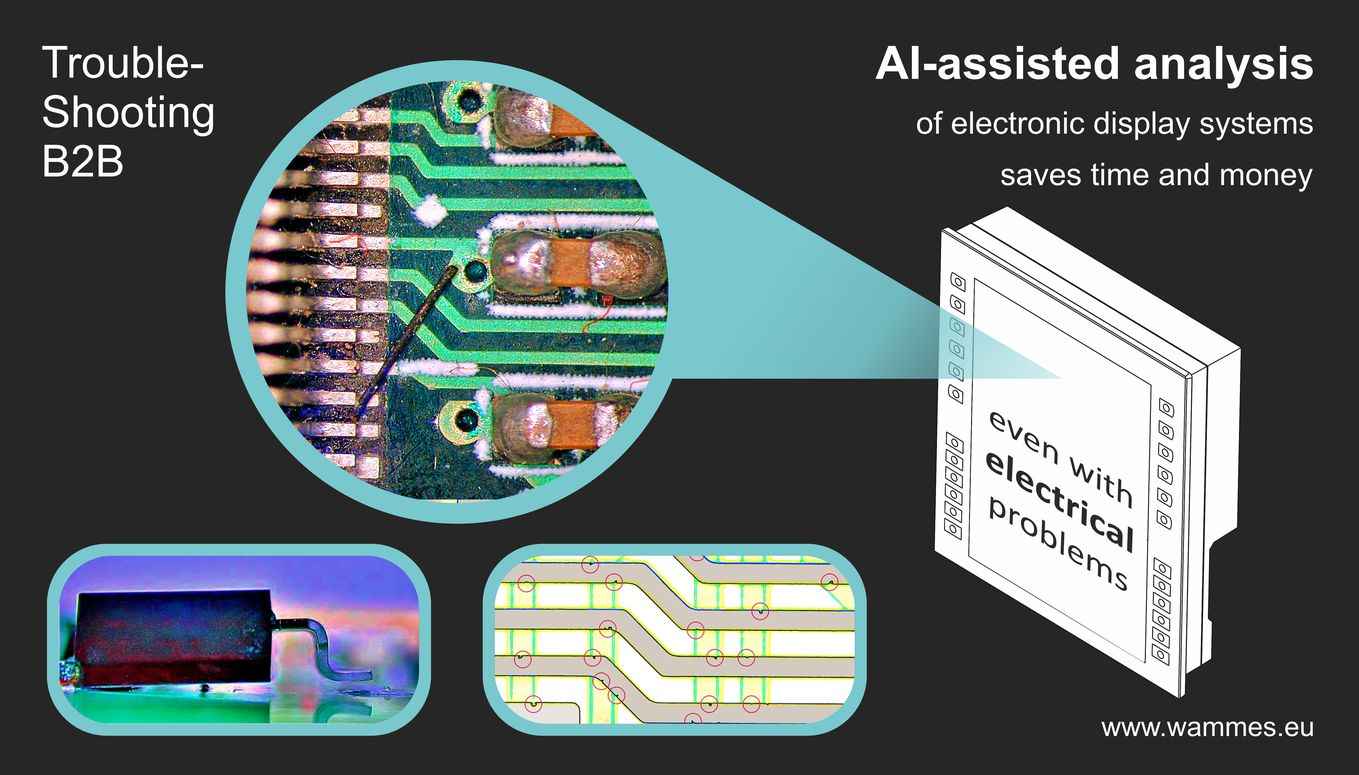

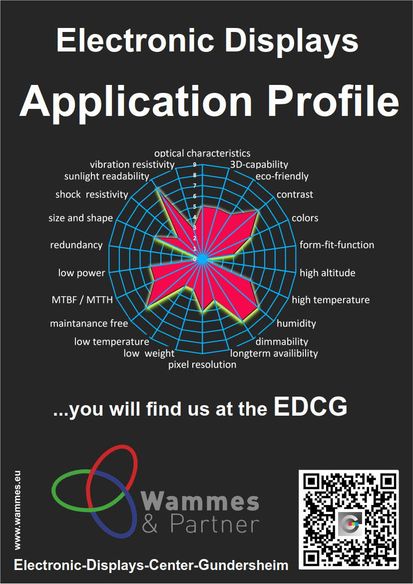

This results in noticeable advantages. For example, the material used no longer needs to be mechanically deformable. Consequently, more stable materials can be used that have different properties, appearances or higher transparency. The surface can also be structured, contoured, even curved or domed. In addition, this technology enables a function that previously could only be implemented at enormous expense: multi-touch, i.e. the simultaneous detection of different commands at several locations. However, the algorithm must be capable of learning and requires processing resources. The more and the faster these can be used, the more likely the result will be to be error-free.

As if by magic

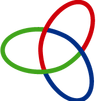

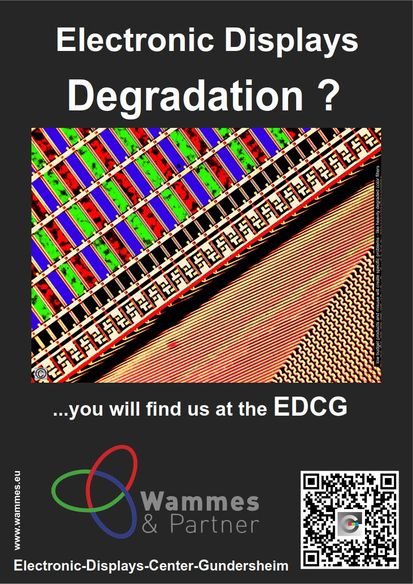

Because: With solid-state solutions comes a new error variant, the so-called ghost touch. Here the algorithm erroneously assumes requests that have never existed before. Since the disturbance of the idle state of the touch sensor is caused by the fact that transmitting power is deducted or the receiver is obstructed in any way, it is not yet known whether there is an actual intention - in other words, whether a finger or an operator has triggered this disturbance or something else. Interference can also be caused, for example, by raindrops, a bunch of keys, or the installation of a shoring. For example, if the housing is partly made of plastic and metal and thus has different conductivity, the propagation of the electrical fields in the areas of influence of the electrically conductive material changes. The entire matrix of the input surface is no longer homogeneous. The new properties must be calibrated and taken into account statically as well as dynamically. The same applies to additional external or internal electromagnetic fields such as WLAN, Bluetooth, radio remote controls or EMC. Even an unstable or clumsy grounding concept in the cabling of the system can, through dynamic changes in electrical potentials, favour or generate misinterpretations and thus ghost touches.

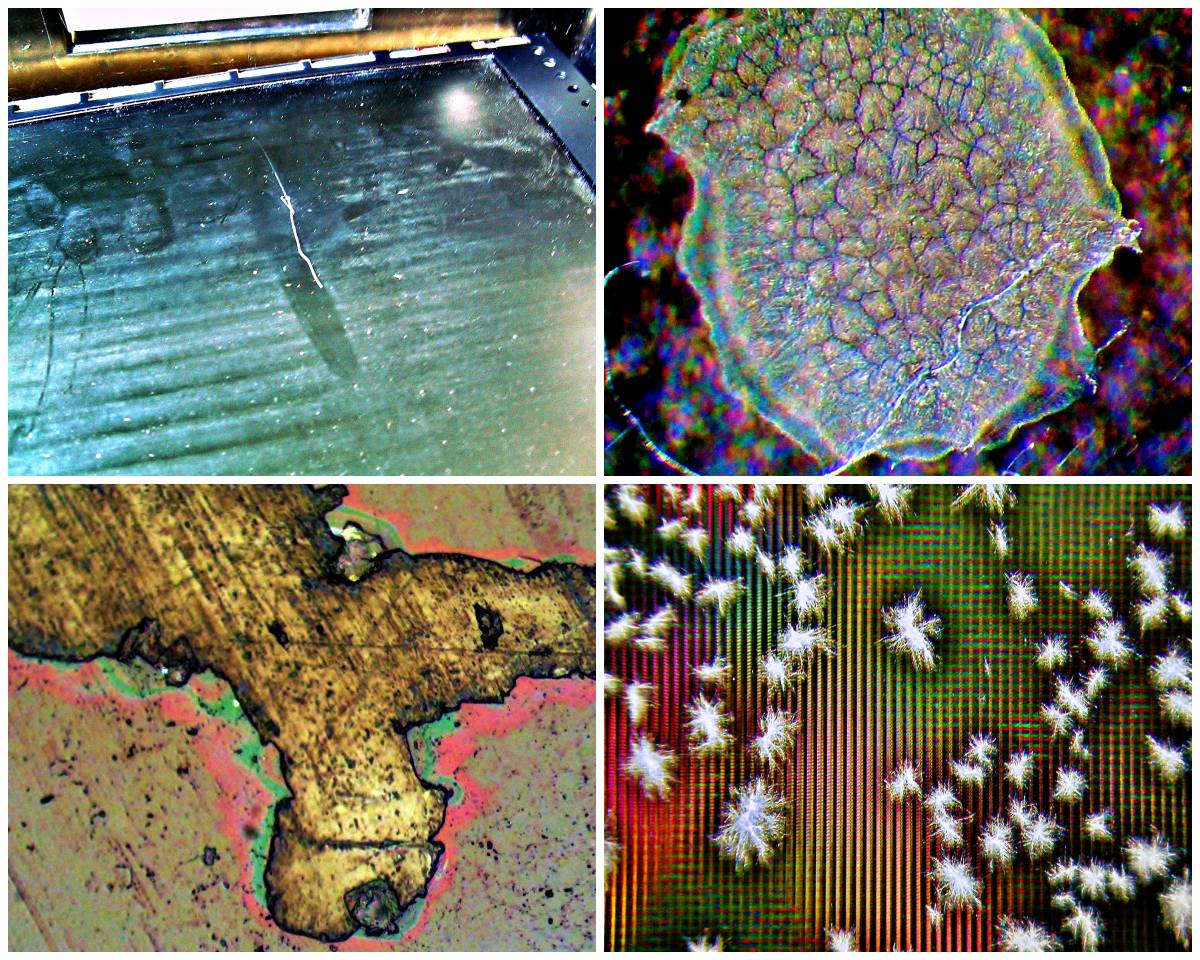

This is especially true for differently coated displays. Both the self-generated electrical fields and the external interferers are subject to the same laws. Therefore, the different dielectric constants of the respective materials or their combinations between the influencing finger or aid and the transmitter or receiver also have an effect here. Since these are basically alternating fields, all influences are also frequency-dependent. This means that the complexity of the possible influences is much greater than in previous electromechanical systems. The type of influences is also not comparable with previous systems. Therefore it is essential to go through a new learning curve - and to master it.

With the new PCT touch systems, everyone who designs these new touches, whether they like it or not, has to deal very intensively with the software and firmware and their possibilities and limits for the selected touch system, including its integration. The calibration of the algorithm, for example, on an additional protective screen, proves to be not so easy in practice, as this is only a theoretical constant. In reality, exactly the same application, for example in optical bonding, is rarely successful. Furthermore, at some point this layer is impaired, scratched, abraded, brittle, dirty or degraded and may provoke other commands in this segment. This means that the algorithm has to learn that over time the standard pattern has changed in some way and that the current state is the new reference.

Finally, a not inconsiderable loss of operating safety is lost when decoupling from the mechanics: Operators lack feedback, i.e. the direct, tactile signal that they have made contact and thus triggered a command. Without a software-generated signal from the computer, they do not know whether the request has been recognized or understood. This feedback must be artificially created and must be provided as quickly as possible, ideally in real time. There is no point in entering an urgent command and repeating the entry several times if there is no response. Otherwise the request may even be misinterpreted at the end or a critical situation may not be stopped in time.